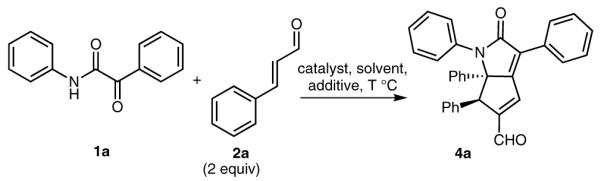

Table 1.

Optimization of the Reaction Conditions

| ||||||

|---|---|---|---|---|---|---|

|

| ||||||

| ||||||

|

| ||||||

| Entrya | Catalyst | Solvent | Time (d) | Additiveb | Yieldc (%) | eed (%) |

| 1 | 3a | CH2Cl2 | 3 | – | 18 | n.d. |

| 2 | 3b | CH2Cl2 | 3 | – | – | n.d. |

| 3 | 3c | CH2Cl2 | 3 | – | – | n.d. |

| 4 | 3d | CH2Cl2 | 3 | – | 6 | n.d. |

| 5 | 3e | CH2Cl2 | 3 | – | 47 | 97 |

| 6 | 3e | CH2Cl2 | 5 | – | 55 | 87 |

| 7 | 3e | EtOH | 5 | – | 21 | 69 |

| 8 | 3e | i-PrOH | 5 | – | 49 | 73 |

| 9 | 3e | EtOHe | 2 | – | 38 | 32 |

| 10 | 3e | i-PrOHe | 2 | – | 32 | 47 |

| 11 | 3e | CH2Cl2 | 5 | NaOAc | 63 | 97 |

| 12 | 3e | CH2Cl2 | 5 | K2CO3 | 39 | 53 |

| 13 | 3e | CH2Cl2 | 5 | Na2CO3 | 27 | 58 |

| 14f | 3e | CH2Cl2 | 6 | NaOAc | 45 | 94 |

| 15g | 3e | CH2Cl2 | 6 | NaOAc | 60 | 94 |

| 16 | 3e | CH2Cl2 | 3 | NaOAc | 47 | 93 |

Reaction conditions: 0.3-mmol scale using 1a (1 equiv), 2a (2 equiv), catalyst 3a–e (20 mol%), solvent (1 mL), r.t. Only one diastereomer was observed.

20 mol% of the additive was used.

Yield of the isolated product 4a after flash column chromatography.

Determined by HPLC on a chiral stationary phase; n.d. = not detected.

The reaction was heated to reflux for 2 d.

A ratio 1.6:2 of 1a/2a was used.

A ratio 1:2.5 of 1a/2a was used.