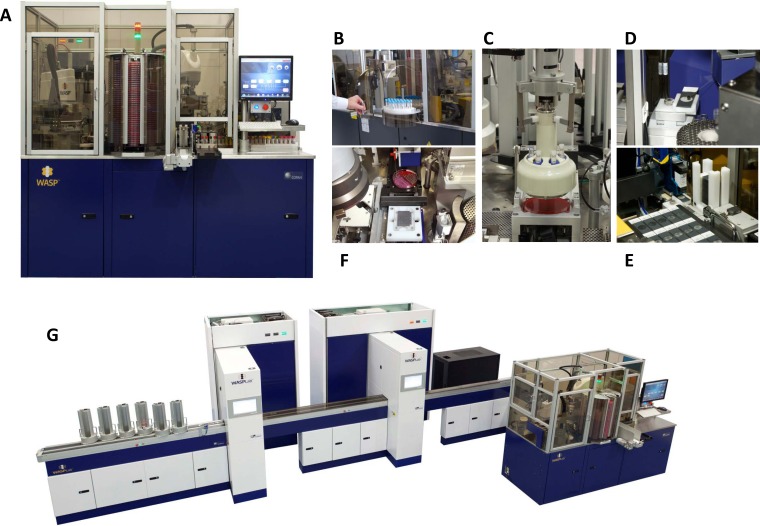

FIG 10.

Walk-away specimen processor (WASP). The multifunctional WASP core unit (A) includes two independently operating robotic arms capable of decapping, recapping, and inoculating up to 180 solid agar plates per hour. The core unit is also equipped with a vortex for sample mixing and a “tool belt” which can accommodate three different-size reusable calibrated inoculating loops and a blunt tipped colony-picking instrument which can be accessed by the robotic arm as needed. Culture media are housed in a 9-silo carousel which can accommodate up to 350 standard agar plates. Liquid media for broth culture are housed in a “warehouse carousel” located on the reverse side of the WASP (B). The WASP is also equipped with a barcode label reader capable of reading specimen barcodes and a printer which automatically prints and applies labels to all corresponding plates prior to inoculation. The core WASP unit can be equipped with optional disk dispenser (C) for application of antibiotic disks to inoculated media, a Gram slide prep module for automated preparation of slides (D and E), and a stage for automated transfer of isolated colonies and matrix material to a MALDI target plate for analysis using MALDI-TOF MS (F). Total laboratory automation features the WASP core unit connected via conveyer tracks to smart incubators equipped with high-resolution cameras for imaging of culture plates (G). (Courtesy of Copan Diagnostics.)