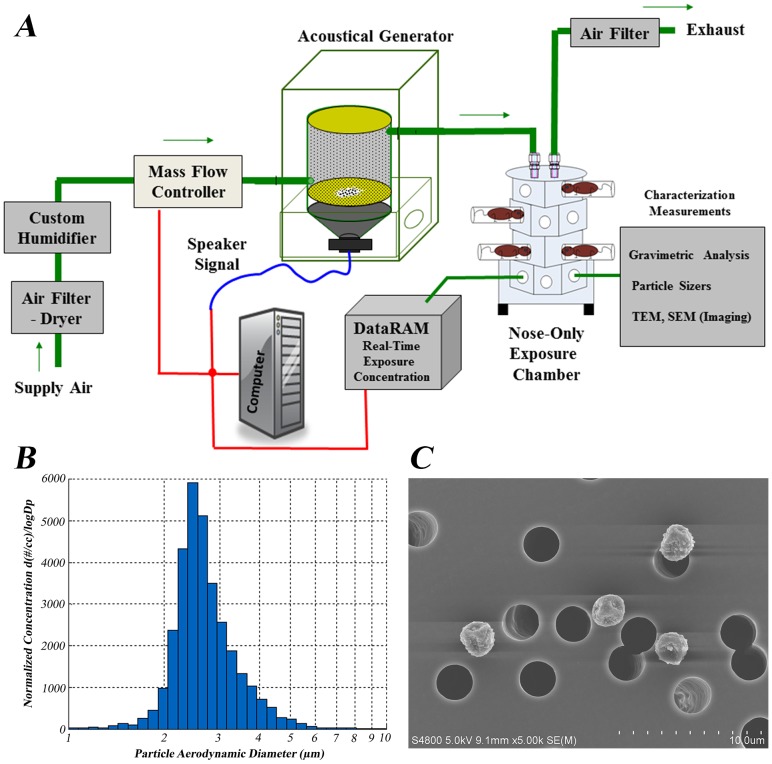

Figure 1. Preliminary acoustical generator exposure chamber experiments.

A) Illustration showing the acoustical generator inhalation exposure system. Supply air is HEPA filtered and directed into the acoustical generator. The acoustical generator is then sent a signal to vibrate at a designated frequency resulting in the formation of fungal aerosols from inoculated rice grains. The fungal aerosol is then directed into a multi-animal, nose-only chamber. After passing through the animal's breathing zone the air is filtered before being sent into the exhaust system. A real-time particle counter attached to the computer calculates the concentration of fungal particles being deposited into the airways, and the DataRAM reports that number to the computer, which can be altered during the exposure to obtain the desired deposition concentration. B) The Aspergillus fumigatus aerosol particle size distribution produced by the acoustical generator. The size of single or aggregate A. fumigatus conidia is 2–5 µm. C) Field emission scanning electron microscopy image of A. fumigatus fungal conidia deposited on a polycarbonate filter collected from one of the sampling ports of the nose-only exposure chamber.