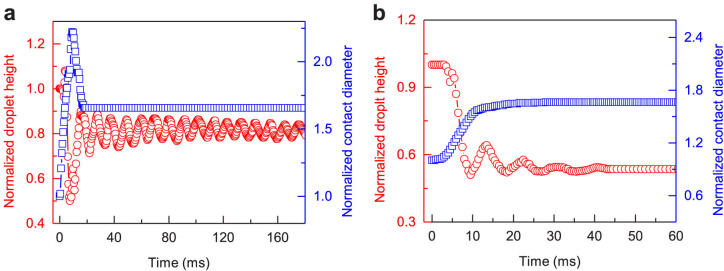

Figure 3. Droplet oscillation suppression in the transient response of EWOLF.

(a–b) Transient responses of the activating droplet characterized by the normalized contact diameter (l/l0) and droplet height (h/h0) on the PTFE membrane (a) and the liquid infused film (b). During the electrowetting, the transient response of droplet displays two distinctive modes, which are MCL and CCL modes, respectively. In the MCL stage, the maximum contact diameter in EWOD overshoots its final steady-state value, suggesting the under-damped oscillation nature of the activating drop. In the CCL stage, the droplet height attains periodical oscillations. By contrast, for the case of EWOLF, the normalized contact diameter progressively increases without retraction in the MCL stage and droplet oscillation in the droplet height is substantially reduced. Moreover, the response time for the droplet to reach a steady state is ~45 ms, representing over 90% reduction compared to that in EWOD. Such a droplet oscillation suppression in the transient response of EWOLF is ascribed to the introduction of viscous liquid lubricant in the porous PTFE matrix, which allows for the formation of additional wetting ridges at the periphery of the droplet as well as viscous liquid-liquid interfaces underneath the droplet.