Abstract

Background

Construction industry is among the most hazardous industries, and needs a comprehensive and simple-to-administer tool to continuously assess and promote its health and safety performance.

Methods

Through the study of various standard systems (mainly Health, Safety, and Environment Management System; Occupational Health and Safety Assessment Series 180001; and British Standard, occupational health and safety management systems-Guide 8800), seven main elements were determined for the desired framework, and then, by reviewing literature, factors affecting these main elements were determined. The relative importance of each element and its related factors was calculated at organizational and project levels. The provided framework was then implemented in three construction companies, and results were compared together.

Results

The results of the study show that the relative importance of the main elements and their related factors differ between organizational and project levels: leadership and commitment are the most important elements at the organization level, whereas risk assessment and management are most important at the project level.

Conclusion

The present study demonstrated that the framework is easy to administer, and by interpreting the results, the main factors leading to the present condition of companies can be determined.

Keywords: construction, continuous improvement, health, safety

1. Introduction

Studies indicate that construction industry is among the most hazardous industries. According to the National Safety Council reports, 8,993 people died during 2003–2011 at construction workplaces in the United States, which was the highest number of fatalities among deaths occurring in all types of industries over this period of time. The same trend was observed in other countries as well. The situation is even worse in developing countries [1,2]. Working at a height, using different types of machines and equipment (for example, cranes, as one of the most commonly used machines in the construction industry, cause more than 50 deaths each year), dermal and inhalation exposure to different hazardous materials (such as silica dust and asbestos), inappropriate practices, awkward postures, employing workers from other countries with different languages and cultures, and the variable nature of working conditions pose a large number of unacceptable risks to all those who are dealing with construction projects, including workers, engineers, project managers, and so on [3,4]. Moreover, studies conducted in this field have revealed that a lack of attention to occupational health and safety (OH&S) issues results in irreversible costs, including costs associated with workplace accidents, reworking, delays, and loss of reputation of the organization and contractor [5].

As a consequence, in recent years, in addition to the triangle of time, cost, and quality, OH&S issues are increasingly being emphasized as an indicator for construction project success [6,7]. For these reasons, construction companies need an appropriate tool to continuously assess and improve their conditions with respect to OH&S.

Traditionally, accident or incident rates were used, but there is always an uncertainty about the accuracy of such reports; in addition, these indicators are retrospective in nature and provide information about what happened in the past. The safety performance evaluation (SPE) framework proposed by Ng et al [8] is more comprehensive, structured, and organized than previous tools. In this framework, seven and six main factors and their related subfactors had been determined at organizational and project levels, respectively; using them, two questionnaires were designed. The average score at these two levels would be considered as the final score of contractors. However, there are some problems with the SPE framework; for example, the safety performance of contractors, which is necessary to determine the extent of progression after the implementation of corrective actions, has not been quantified. Ai Lin Teo and Yean Yng Ling [9] provided another framework for assessing the performance of the safety management system at construction sites. Although the framework had some powerful features, it had not been used extensively due to the lack of a comprehensive, generally accepted, and standard basis. In fact, to achieve a continuous improvement in OH&S issues at a construction company, a combination of the aforementioned frameworks along with a well-established bedrock principle is needed.

Various models and standards are available that address OH&S assessment and improvement in various kinds of industries; Health, Safety, and Environment Management System (HSE-MS) and Occupational Health and Safety Assessment Series (OHSAS) 18001 are among the most popular ones. The HSE-MS, based on the plan–do–check–act methodology, is a cyclical process intending to achieve continuous improvement in health, safety, and environment at workplaces. A correctly implemented HSE-MS can result in declined accident rates, reduced number of injuries, lower waste generation, and more productivity. It is worth pointing out that various elements for HSE-MS may be expressed by different companies or guidelines; however, the key elements are the same (plan–do–check–act) [10,11]. The OHSAS 18001 is also a risk management system that is widely used to identify and manage unacceptable risks at workplaces. It is very similar to HSE-MS in terms of both basis and purpose. The British Standard, occupational health and safety management systems-Guide (BS 8800: 2004), is another useful tool to meet these objectives. Although the standard was basically developed for the United Kingdom, it has been adapted by other countries such as Finland.

Considering the strengths and weaknesses of previous frameworks, in this study, we aimed to provide a new framework that not only covers all drawbacks of the previous frameworks, but is also more simple and comprehensive.

2. Materials and methods

In total, eight safety- and health-related management systems, including OHSAS 180001, HSE-MS, ISO 14001 (Environmental Management System), ISO 50001 (Energy Management), ISO/IEC 27001 (Information Security Management), ISO 20121 (Sustainable Events Management), BS 8800, and AS/NZS 4801 (Australia Standard of Occupational Health and Safety Management Systems), were reviewed to define a framework for evaluating OH&S performance of construction companies. Three of them, HSE-MS, OHSAS 180001, and BS 8800, were singled out as the framework inputs. These systems have widely been used and also are easy to administer. Based on them, seven main elements—“leadership and commitment,” “policy and strategic objectives,” “organization, resources, and documentation,” “risk assessment and management,” “planning,” “implementation and monitoring,” and “measuring performance, auditing, and reviewing”—were selected. By reviewing the literature, factors that would affect these seven elements at two levels (organization and project) were discerned [12–15]. The study was carried out in four steps. Questionnaire designing was the first step in which two sets of questionnaires were designed using the main elements and related factors, which were identified in the first part of the study. The main elements were scored on a seven point scale, ranging from 1 (very important) to 7 (less important), whereas a five-point scale ranging from 1 (very important) to 5 (less important) was used to score their related factors. The designed questionnaire was then sent out to 15 respondents, including university professors and PhD candidates, who were experts in OH&S issues. The consensus was achieved in the second round. The questionnaire reliability was determined using kappa coefficient. After that, the finalized questionnaires were sent to 75 people, including employers, contractors, and health and safety experts, who were involved in constructional affairs in some way. They were asked to assess the importance of each element and its related factors.

Calculation of the relative importance of the elements and their related factors was the second step of the study. The relative importance was computed with the method used by Assaf et al [16] as follows:

For the elements, calculations were performed based on mean ranking (MR):

| [1] |

| [2] |

In Equation 1, r is ranking and f is the frequency for that ranking, and N is the total number of responses; in Equation 2, RIj is the relative importance of the jth element.

For related factors, mean scoring (MS) was used to calculate RI:

| [3] |

| [4] |

In Equation 3, s is the score of each factor, f the frequency of each rating, and N the total number of responses to each factor; in Equation 4, RIij is the relative importance of the ith factor related to the jth element and MSij is the mean score of the ith factor related to the jth element.

In the third step, the performance index was calculated; elements and their factors and also the true performance of contractors with respect to OH&S issues were combined in one index, using the following equation:

| [5] |

Here PIij is the performance index of the ith factor related to the jth element and PW the score of true performance of contractors (1 = very poor, 2 = poor, 3 = normal, 4 = good, and 5 = very good). In the fourth step, contractor performance was quantified. The summation of all PIij scores is equal to the contractor total score (Equation 6). Table 1 shows a schematic of the final version of the framework that we were intended to achieve.

| [6] |

Table 1.

Schematic of the final framework to evaluate the final performance index of a contractor; n is the number factors related to each element

| Elements (j) | Related factors (i) | True performance of contractors |

||||

|---|---|---|---|---|---|---|

| Very poor (1) | Poor (2) | Normal (3) | Good (4) | Very good (5) | ||

| 1 | 1 | PI11 | PI11 | PI11 | PI11 | PI11 |

| 2 | PI21 | PI21 | PI21 | PI21 | PI21 | |

| 3 | PI31 | PI31 | PI31 | PI31 | PI31 | |

| . | . | . | . | . | . | |

| . | . | . | . | . | . | |

| . | . | . | . | . | . | |

| n | PIn1 | PIn1 | PIn1 | PIn1 | PIn1 | |

| 2 | . | . | . | . | . | . |

| 3 | . | . | . | . | . | . |

| 4 | . | . | . | . | . | . |

| 5 | . | . | . | . | . | . |

| 6 | . | . | . | . | . | . |

| 7 | . | . | . | . | . | . |

PI, performance index.

Here, TPI is the total performance index for each contractor. According to TPI, contractor's performance was classified into five groups: very poor, poor, normal, good, and very good. All the above mentioned functions were computed at organizational and project levels.

In the final part of study, the developed framework was run in three contractor companies and the obtained results were compared.

3. Results

After determining the main seven elements (leadership and commitment; policy and strategic objectives; organization, resources, and documentation; risk assessment and management; planning; implementation and monitoring; and measuring performance, auditing, and reviewing), factors affecting these elements were recognized through the study of literatures and guidelines, including 117 and 120 factors at organizational and project levels, respectively. Table 2 shows the number of related factors for each element at organizational and project levels, and some of these factors are given in Table 3.

Table 2.

Number of criteria and corresponding subcriteria for each element at organizational and project levels

| Criteria | Number of subcriteria |

|

|---|---|---|

| Organizational level | Project level | |

| Leadership and commitment | 6 | 1 |

| Policy and strategic goals | 11 | 2 |

| Organization, resources, and documentation | 47 | 41 |

| Evaluation and risk management | 8 | 36 |

| Planning | 21 | 18 |

| Implementation and monitoring | 13 | 17 |

| Auditing and reviewing | 11 | 5 |

| Total | 117 | 120 |

Table 3.

Some examples of subcriteria affecting the main criteria

| Criteria | Subcriteria at organizational level | Subcriteria at project level |

|---|---|---|

| (1) Leadership and commitment | Developing OH&S policy Allocating required resources (financial, human, and physical) to achieve OH&S objectives Active participation in implementation of programs Attending meetings at all levels (organizational, client, and project) Attending OH&S cultural programs Attending OH&S participatory and motivational programs |

Managerial participation in investigation of accidents/diseases and implementation of corrective measures |

| (2) Policy and strategic objectives | Developing and announcing OH&S policy Declaration of commitment to OH&S regulations for achieving OH&S goals Developing OH&S strategic goals Scheduling measures, responsibilities, and resources for the predefined purposes as well as determining monitoring indicators Setting new goals if the previous ones have not been met |

Availability of safety and health policies for employees Degree of personal awareness about those policies |

| (3) Organization, resources, and documentation | Establishing an organizational structure to manage OH&S issues Defining responsibilities and duties of each OH&S committee member Selecting OH&S management representatives to introduce them to client Allocating resources needed to conduct OH&S training Developing procedures and criteria for employees’ recruitment |

Ensuring that every action is in compliance with the existing policies Employing safety and health professionals according to the approved organizational codes Assessing training needs with respect to safety and health considerations at all organizational levels Providing a scheduled training program in respect of safety and health considerations Ensuring that meetings of safety and health committee are held Ensuring that employees participate in safety and health programs |

| (4) Evaluation and risk assessment | Specifying a procedure for identifying and assessing potential hazards Identifying the role of risk assessment in setting policies, strategic objectives, and corrective/preventive actions Assessing the rate of progress in performance indicators Determining the compliance level between strategic goals and performance indicators Developing procedures for applying control measures to eliminate or reduce risks |

Identifying and evaluating how risks associated with routine and nonroutine operations Determining how risks are prioritized Using the results of risk assessment to develop or redesign training programs Recording and maintaining the result of hazardous chemical or physical agents Implementing control measures based on risk assessment result |

| (5) Planning | Setting responsibilities for developing OH&S plans Announcing capital integration for procedures Managing potential changes to ensure control of the resulting risks Informing all about the changes in processes, procedures, and guidelines Developing and establishing emergency management procedures Determining emergency situations according to OH&S risks as well as their probable environmental impacts |

Providing contractors with a safety and health plan at the construction site Using new and alternative technologies such as Geographic Information System (GIS)-based methods for improving safety and health issues in companies Involving personnel in procurement of health and safety equipment such as personal protective equipment |

| (6) Implementation and monitoring | Setting transparency of duties and responsibilities in organizations, procedures, and guidelines Devising a procedure for documenting all records and their control Monitoring OH&S performance criteria periodically in the organization Adopting a formal procedure to report, record, and analyze accidents/near misses |

Implementing corrective/preventive measures Performing periodic medical examination at regular intervals Measuring and monitoring hazardous agents at work Reporting near misses Assessing effectiveness of corrective/preventive measures |

| (7) Auditing and reviewing | Developing internal auditing procedures Developing management reviewing procedures Using a written schedule for periodic internal audit of the organization Reviewing the management system according to specific input standard requirements (OHSAS 18001/ISO 14001/HSE-MS) |

Recording the results and internal auditing checklists Reporting the result of internal auditing within the organization Assessing auditors' competence periodically Analyzing the root causes of noncompliance mentioned in audit reports |

HSE-MS, Health, Safety, and Environment Management System; OHSAS, Occupational Health and Safety Assessment Series; OH&S, occupational health and safety.

Subsequently, according to the respondents’ (75 experts in construction affairs) viewpoints, the relative importance of each element and its corresponding factors was evaluated.

The response rate for organization and project questionnaires were 64% and 36%, respectively. Eight employers, 13 project managers, and 27 OH&S professionals completed the organizational questionnaire, whereas four employers, six project managers, and 17 OH&S professionals completed the project questionnaire.

Table 4 shows the results from the questionnaire survey. According to the obtained results, the most important element at the organizational level is “leadership and commitment,” whereas that at the project level is “evaluation and risk management.” These results are in agreement with the number of related factors (Table 2) detected for each criterion. For example, the number of factors for leadership and commitment reduces from six items at the organizational level to one item at the project level. The element evaluation and risk management has just eight related factors at the organization level but 36 factors at the project level. As the research results suggest, “auditing and reviewing” has almost the same importance at both levels.

Table 4.

Result of MR, RR, and RI for each criterion at organizational and project levels

| Criteria | MR |

RR |

RI |

|||

|---|---|---|---|---|---|---|

| O | P | O | P | O | P | |

| Leadership and commitment | 1.00 | 5.40 | 1 | 6 | 0.374 | 0.075 |

| Policy and strategic goals | 2.47 | 6.06 | 2 | 7 | 0.151 | 0.067 |

| Organization, resources, and documentation | 2.47 | 4.50 | 2 | 4 | 0.151 | 0.089 |

| Evaluation and Risk management | 3.81 | 1.10 | 3 | 1 | 0.098 | 0.357 |

| Planning | 4.77 | 2.69 | 4 | 3 | 0.078 | 0.136 |

| Establishing and monitoring | 5.17 | 2.22 | 6 | 2 | 0.072 | 0.182 |

| Auditing and reviewing | 4.90 | 4.81 | 5 | 5 | 0.076 | 0.084 |

MR, mean ranking; O, organization; P, project; RI, relative importance; RR, relative ranking.

After determining the relative importance of each element and its related factors at the organization level, Table 5 was prepared. According to the values presented in the last row, which is the sum of upper quantities, contractor’s performance index at the organizational level was categorized into five groups given in Table 6.

Table 5.

Schema of finalized framework for the organization level

| Element (j) | Related factor (i) | True performance of company |

||||

|---|---|---|---|---|---|---|

| Very poor (1) | Poor (2) | Normal (3) | Good (4) | Very good (5) | ||

| 1 | 1 | 1.47 | 2.94 | 4.40 | 5.87 | 7.34 |

| 2 | 1.53 | 3.06 | 4.59 | 6.12 | 7.64 | |

| 3 | 1.02 | 2.04 | 3.06 | 4.08 | 5.10 | |

| 4 | 1.55 | 3.11 | 4.66 | 6.22 | 7.77 | |

| 5 | 1.05 | 2.10 | 3.16 | 4.21 | 5.26 | |

| 6 | 0.86 | 1.71 | 2.57 | 3.42 | 4.28 | |

| 2 | 1 | 0.32 | 0.64 | 0.96 | 0.128 | 1.60 |

| 2 | 0.31 | 0.62 | 0.93 | 0.124 | 0.156 | |

| 3 | 0.25 | 0.51 | 0.76 | 1.02 | 1.27 | |

| . | . | . | . | . | . | |

| . | . | . | . | . | . | |

| 3 | . | . | . | . | . | . |

| 4 | . | . | . | . | . | . |

| 5 | . | . | . | . | . | . |

| 6 | . | . | . | . | . | . |

| 7 | ||||||

| Total | 60 | 120 | 180 | 240 | 300 | |

Table 6.

Company performance classification based on the TPI scores at the organizational level

| Total score | Company performance |

|---|---|

| <60 | Very poor |

| 60–120 | Poor |

| 120–180 | Normal |

| 180–240 | Good |

| 240–300 | Very good |

TPI, total performance index.

The same process was carried out at the project level, and Table 7 was prepared. Using the total scores, a performance index was developed, as shown in Table 8.

Table 7.

Schema of finalized framework provided for the project level

| Element (j) | Related factor (i) | True performance of company |

||||

|---|---|---|---|---|---|---|

| Very poor (1) | Poor (2) | Normal (3) | Good (4) | Very good (5) | ||

| 1 | 1 | 1.5 | 3 | 4.5 | 6 | 7.5 |

| 2 | 1 | 0.64 | 1.28 | 1.93 | 2.57 | 3.21 |

| 2 | 0.7 | 1.4 | 2.09 | 2.79 | 3.49 | |

| 3 | 1.78 | 3.56 | 5.34 | 7.12 | 8.90 | |

| . | . | . | . | . | . | |

| . | . | . | . | . | . | |

| 3 | . | . | . | . | . | . |

| 4 | . | . | . | . | . | . |

| 5 | . | . | . | . | . | . |

| 6 | . | . | . | . | . | . |

| 7 | ||||||

| Total | 80 | 160 | 240 | 320 | 400 | |

Table 8.

Classification of company performance at the project level based on the TPI scores

| Total score | Contractor performance |

|---|---|

| <80 | Very poor |

| 80–160 | Poor |

| 160–240 | Normal |

| 240–320 | Good |

| 320–400 | Very good |

TPI, total performance index.

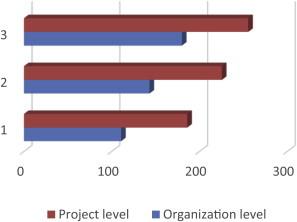

The results of implementing the provided framework in three construction companies are shown in Fig. 1. According to the results at the organization level, the OH&S-related performance of the first contractor was classified to be poor, while two others had normal performance. At the project level, a similar trend was observed, except for contractor 3 whose performance was evaluated to be “good.” The research findings revealed that the framework was easy to implement in the aforementioned companies.

Fig. 1.

OH&S conditions in three companies determined by the present framework. OH&S, occupational health and safety.

4. Discussion

The importance of OH&S considerations in the construction industry cannot be overemphasized. So far, a lot of frameworks have been proposed by different researchers from different countries to assess and promote OH&S issues in the construction industry, each of which has its own drawbacks. Some research works [8,17] focused only on safety issues in the construction industry, regardless of the existing health hazards. Near miss reporting, as an important aspect of sound OH&S management systems, has been ignored in many similar studies. All construction companies must have a formal system for near miss reporting, According to Reason [18], it would be a sign of good safety culture in the company. Changes in working conditions and locations are an inevitable part of the construction industry. Therefore, it is necessary to manage them properly. Several researchers, such as Tam et al [19] and Aksorn and Hadikusumo [20], reviewed criteria affecting OH&S at construction sites, but they did not differentiate between relative importance of the main criteria and their related subcriteria at organizational and project levels. Considering the aforementioned drawbacks, the output of this study is a simple-to-administer and comprehensive framework that enables construction companies to continuously monitor and improve their performance with respect to OH&S issues. The OHSAS 18001, HSE-MS, and BS 8800 are the main sources that helped meet these objectives. They form the basis of several related studies. Abbaspour et al [21], for instance, used the HSE-MS proposed by the Exploration and Production (E&P) forum to create a framework to assess company performance with respect to environmental issues. Zeng et al [22] declared that adopting OHSAS 18001 standards can improve OH&S status at construction firms.

The results of the present study showed that “leadership and commitment” is the most important element affecting OH&S at the organizational level, whereas “risk assessment and management” is of outmost importance at the project level. As reported by Behm [23], 42% of fatalities are related to a lack of safety considerations at the conceptual phase of a construction project. The present study shows that OH&S issues at the project level are influenced by decisions that are made at the organizational level; hence, a high number of fatalities can be prevented by good leadership and commitment from company managers. Company managers can indirectly affect OH&S at a construction site by developing a good OH&S policy, allocating required resources, and in some cases, attending OH&S-related meetings and parties. However, at the project level, hazards are sensed by employees more than anywhere. Consequently, hazard identification, safety training, control measures, and personal protective equipment are more important than other elements.

According to the study conducted by Hinze et al [24], this framework can be considered a leading tool by which the current situation of a construction company with regard to OH&S can be figured out, and in the next step, the most affecting elements and related factors attributing to this situation can be determined; finally, corrective actions can be taken based on the previous steps.

In conclusion, from an OH&S perspective, the construction industry can be classified as a critical industry. Hence, it is essential to adopt a regular monitoring program to improve its situation in terms of OH&S considerations. The framework proposed in the present study can be applied as a useful tool to achieve this objective. The framework can be presented in the form of a two-page spreadsheet package to save time and resources.

Conflicts of interest

The authors report no conflict of interest in the undertaking of this research.

Footnotes

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

References

- 1.National Safety Council . 2013 ed. National Safety Council; USA, Itasca, Illinois: 2013. Injury facts. [Google Scholar]

- 2.Gangolells M., Casals M., Forcada N., Roca X., Fuertes A. Mitigating construction safety risks using prevention through design. J Safety Res. 2010;41:107–122. doi: 10.1016/j.jsr.2009.10.007. [DOI] [PubMed] [Google Scholar]

- 3.Zalk D.M., Spee T., Gillen M., Lentz T.J., Garrod A., Evans P., Swuste P. Review of qualitative approaches for the construction industry: designing a risk management toolbox. Saf Health Work. 2011;2:105–121. doi: 10.5491/SHAW.2011.2.2.105. [cited 2011 Jun]. Available from: http://www.e-shaw.net/article/S2093-7911(11)22003-1/fulltext. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Bust P.D., Gibb A.G.F., Pink S. Managing construction health and safety: migrant workers and communicating safety messages. Saf Sci. 2008;46:585–602. [Google Scholar]

- 5.Wang W.-C., Liu J.-J., Chou S.-C. Simulation-based safety evaluation model integrated with network schedule. Autom Constr. 2006;15:341–354. [Google Scholar]

- 6.Ngacho C., Das D. A performance evaluation framework of development projects: an empirical study of Constituency Development Fund (CDF) construction projects in Kenya. Int J Proj Manag. 2013;32:492–507. [Google Scholar]

- 7.Alzahrani J.I., Emsley M.W. The impact of contractors' attributes on construction project success: a post construction evaluation. Int J Proj Manag. 2013;31:313–322. [Google Scholar]

- 8.Ng S.T., Pong K., Skitmore R.M. A framework for evaluating the safety performance of construction contractors. Build Environ. 2005;40:1347–1355. [Google Scholar]

- 9.Ai Lin Teo E., Yean Yng Ling F. Developing a model to measure the effectiveness of safety management systems of construction sites. Build Environ. 2006;41:1584–1592. [Google Scholar]

- 10.American Petroleum Institute. Model environmental, health and safety (EHS) management system. API Publication. Report No.: 9100A. Banker. Report No.: 9100A. 1998 p.

- 11.Azadeh A., Fam I.M., Nouri J., Azadeh M.A. Integrated health, safety, environment and ergonomics management system (HSEE-MS): an efficient substitution for conventional HSE-MS. J Sci Ind Res. 2008;67:403–411. [Google Scholar]

- 12.Sawacha E., Naoum S., Fong D. Factors affecting safety performance on construction sites. Int J Proj Manag. 1999;17:309–315. [Google Scholar]

- 13.Shapira A., Lyachin B. Identification and analysis of factors affecting safety on construction sites with tower cranes. J Constr Eng Manag. 2009;135(1):24–33. [cited 2009 Jan]. Available from: http://ascelibrary.org/doi/abs/10.1061/(ASCE)0733-9364. [Google Scholar]

- 14.Cheng C.-W., Lin C.-C., Leu S.-S. Use of association rules to explore cause–effect relationships in occupational accidents in the Taiwan construction industry. Saf Sci. 2010;48:436–444. [Google Scholar]

- 15.Törner M., Pousette A. Safety in construction—a comprehensive description of the characteristics of high safety standards in construction work, from the combined perspective of supervisors and experienced workers. J Safety Res. 2009;40:399–409. doi: 10.1016/j.jsr.2009.09.005. [DOI] [PubMed] [Google Scholar]

- 16.Assaf S.A., Al-Khalil M., Al-Hazmi M. Causes of delay in large building construction projects. J Manag Eng. 1995;11:45–50. [Google Scholar]

- 17.Fung I.W.H., Tam V.W.Y., Lo T.Y., Lu L.L.H. Developing a risk assessment model for construction safety. Int J Proj Manag. 2010;28:593–600. [Google Scholar]

- 18.Reason J. Ashgate; England, Hampshire: 1997. Managing the risks of organizational accidents. [Google Scholar]

- 19.Tam C.M., Zeng S.X., Deng Z.M. Identifying elements of poor construction safety management in China. Saf Sci. 2004;42:569–586. [Google Scholar]

- 20.Aksorn T., Hadikusumo B.H.W. Critical success factors influencing safety program performance in Thai construction projects. Saf Sci. 2008;46:709–727. [Google Scholar]

- 21.Abbaspour M., Hosseinzadeh Lotfi F., Karbassi A.R., Roayaei E., Nikoomaram H. Development of a model to assess environmental performance, concerning HSE-MS principles. Environ Monit Assess. 2010;165:517–528. doi: 10.1007/s10661-009-0963-0. [DOI] [PubMed] [Google Scholar]

- 22.Zeng S.X., Tam V.W.Y., Tam C.M. Towards occupational health and safety systems in the construction industry of China. Saf Sci. 2008;46:1155–1168. [Google Scholar]

- 23.Behm M. Linking construction fatalities to the design for construction safety concept. Saf Sci. 2005;43:589–611. [Google Scholar]

- 24.Hinze J., Thurman S., Wehle A. Leading indicators of construction safety performance. Saf Sci. 2013;51:23–28. [Google Scholar]