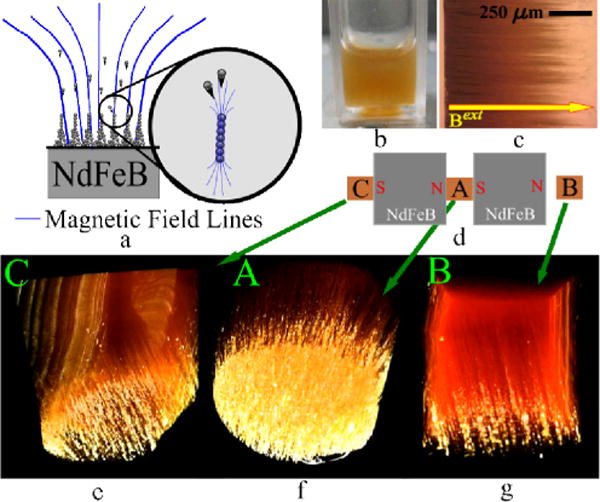

Fig. 1.

(a) Magnetic nanoparticles dispersed in a liquid move towards locations that experience a stronger magnetic field. The particles initially agglomerate into clusters. Strong dipole-dipole interactions amongst clusters enable self-assembly into filaments on the substrate. (b) The nanoparticles are initially uniformly dispersed in liquid PDMS prepolymer. (c) The polymer is cured while the system experiences an externally imposed magnetic field. The polymer matrix preserves the shapes of the self-assembled structures when the field is removed. (d) The structure morphology can be controlled by varying |Bext| and |dBext / dx|, as shown for three experimental conditions obtained by three curing positions relative to a system of two NdFeB permanent magnets. The values obtained, labeled A, B and C, are listed in Table 1. (e–g) Three-dimensional images obtained by X-Ray MicroCT reconstructions demonstrate variations in the microstructure geometry.