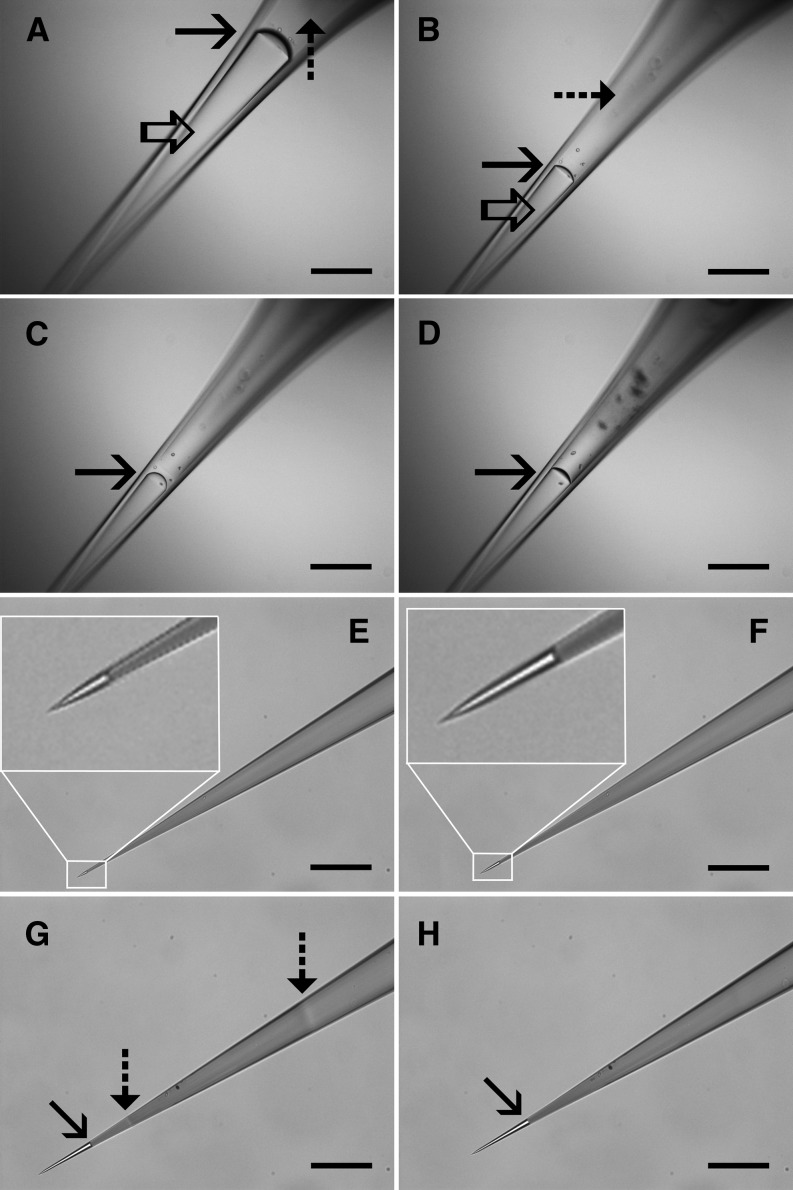

Figure 1.

Production of pico gauges. A to D, Pico gauge production by pressure (method A). A capillary tip is consecutively filled with 10 centistokes (cSt) silicone oil (open arrow) and Loctite 3492 resin (dashed arrow) and submerged into oil (A). The oil/resin boundary is well visible (solid arrow). Application of pressure pushes the oil through the tip and the oil/resin boundary moves forward (B–D). Once the desired oil volume is reached, pressure is reduced, UV light is turned on, and the resin is cured. E to H, Pico gauge production by resin shrinkage (method B). A microcapillary tip is filled completely with resin (in this case, Loctite 352). Submerging the tip into water causes capillary forces to pull in water slowly (E and F, insets). Application of UV light (G) restricted to a small area by the field diaphragm initiates glue curing, indicated by a change in the refractive index (dashed arrow). Shrinkage of the resin pulls water into the tip (solid arrow). Opening the diaphragm cures the remainder of the resin (H). After production of a small volume, the water is exchanged for oil. Bars = 200 μm.