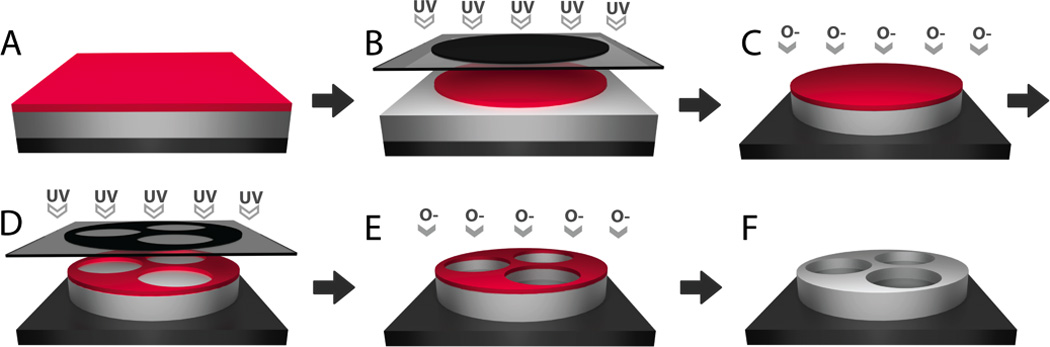

Figure 2.

Photolithography-based techniques for microfabrication of multi-reservoir PMMA devices. A. PMMA and, subsequently, photoresist are spin-cast onto a silicon wafer. B. A circular pattern is transferred from a UV-blocking photomask to the photoresist through UV-induced cleavage. C. Reactive ion etching with oxygen plasma directionally destroys PMMA not protected by the photoresist pattern. D. Following photoresist removal and re-coating of a fresh resist layer, a reservoir-containing pattern is transferred to the photoresist by UV-exposure. E. Reactive ion etching is used to partially etch the PMMA layer to form drug reservoirs. F. Photoresist is chemically removed. Adapted with permission from [34].