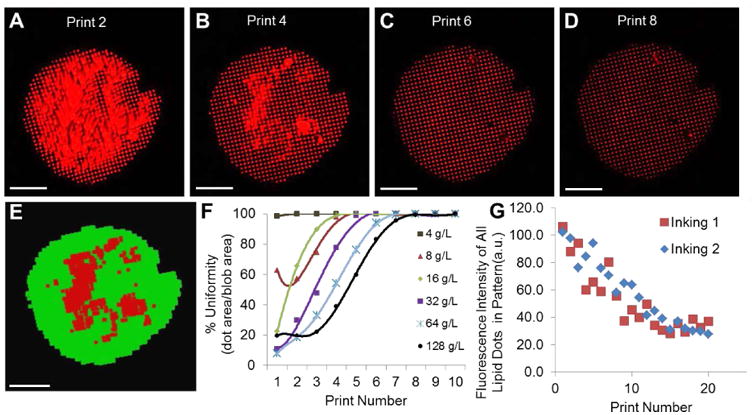

Figure 2.

Uniformity characterization of lipid multilayer structures fabricated by nanointaglio. a-d) Fluorescence image of DOTAP dot patterns from microarrraying and multilayer stamping, representing print numbers 2, 4, 6 and 8, respectively from a liposomal concentration of 32 g/L. Bars = 100 μm. e) Automated quantification of spot uniformity based on recognition of uniform (green) and non-uniform regions (red). Bar = 100 μm. f) Spot uniformity as a function of print number for different ink concentrations; uniform prints obtained after 4-8 prints. e) Dot stamps were inked twice (shown in the graph as inking 1 and 2, respectively) from the same ink-palette. As the ink was depleted from the stamp, the intensities of the individual dots within the lipid pattern decreased linearly in intensity (height) with increasing print number for a constant force (45 Newtons) applied to the stamp. When this constant force was applied, about 20 prints were created before depletion. The similarity in the intensities between the two inkings from the same ink palette indicate the palette is capable of acting as an adequate reservoir for two successive print sequences.