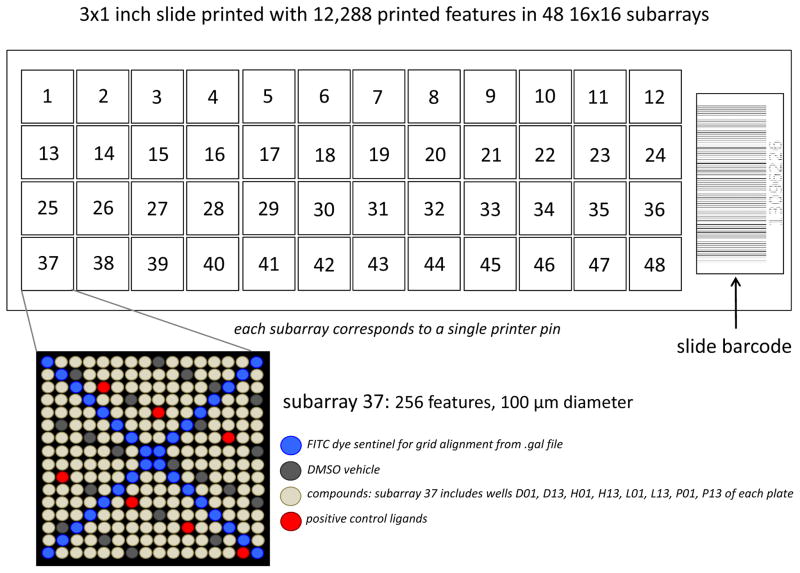

Figure 1. Schematic diagram of a representative printed SMM.

This particular array layout involves 12,288 features arrayed in 48 16×16 subarrays. Printed features are typically 150 μm in diameter for this array density. Each subarray contains 256 features and is created by a single pin from the 48-pin printhead. The subarrays are laid out in the same 4×12 configuration as the printhead. For subarray 37, the pin would pick up samples from wells D01, D13, H01, H13, L01, L13, P01, and P13 of each plates loaded onto the arrayer if printed in sequence. In this configuration, 32 features of each subarray are dedicated to printed dye sentinels for grid alignment (see section on Data Analysis). This configuration also features 20 DMSO vehicle controls and 8 known ligand positive controls per subarray. Positive and negative controls can enable QC analysis of the manufacture and screening processes as well assist in data analysis methods. Barcodes are particularly useful when tracking slide and the barcodes usually correspond to saved .tiff image files for screened slides and .gpr files corresponding to raw data analysis (see section on Screening and Data Analysis).