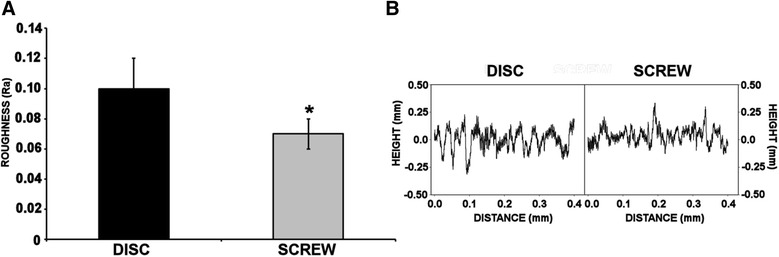

Figure 2.

Measurement of Ti surface roughness of disc and screw. Roughness measurements were conducted using a stylus profilometer (Mitutoyo Surftest SV-2000 Mitutoyo, Halifax, UK) with dedicated analysis software (Surfpak- SV V1.600). (A) Average surface roughness analysed with a contact force of 4 mN and a maximum height range of 800 μm and an evaluation length of 0.4 mm. Values represent means ± S.E.M; N = 5; normalised data analysed by Student t-test; asterisk denotes P < 0.0007. (B) Example of a trace generated for the Ti disc and Ti screw.