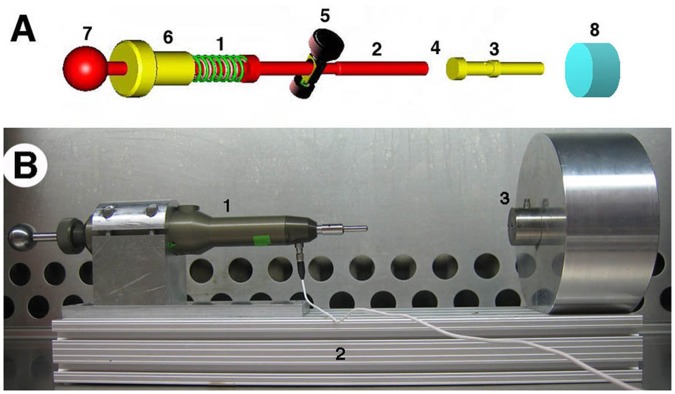

Figure 1.

Set up for delivery of mechanical impact to articular cartilage. (A) Impactor schematics. Compression of the spring in the load mechanism (A1) is controlled by the threaded screw (A6; 1 mm compression/turn) mated with the housing of the impactor (not shown). Thus, the force applied to the missile on spring release is linearly related to the turns of the screw. Compression is accomplished by pulling the tensor knob (A7) until the release mechanism (A5) engages a notch in the piston. Activating the release mechanism (A5) releases the piston (A2) that collides with the interchangeable impactor missile (A3), which ultimately strikes the cartilage (A8). The internal load cell (A4) is placed in line between the piston (A2) and missile (A3), and fixed to the latter. There is sufficient travel between the piston and projectile so that the piston does not contact the missile at the time of cartilage impact. (B) Ex vivo impact of 5 mm cartilage plug, showing impactor (B1) with housing clamped to an aluminum armature (B2) continuous with the sample chamber (B3).