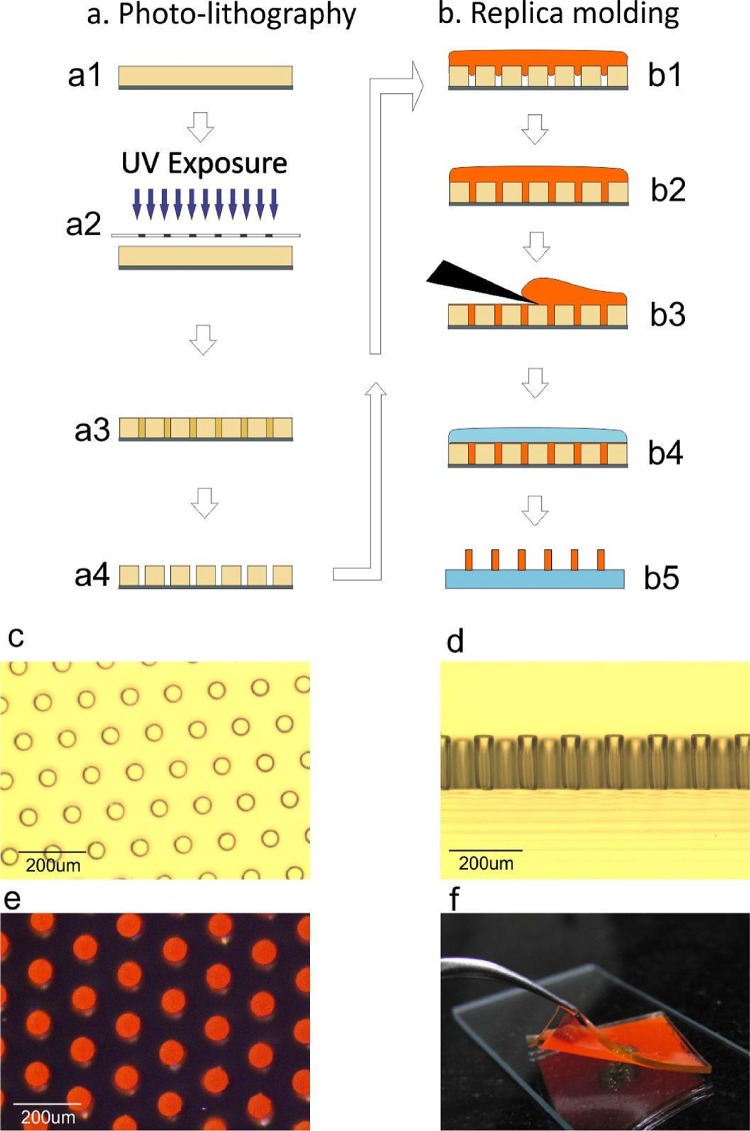

FIG. 2.

(a1) SU8 spin coated on silicon wafer and softbaked (95 °C for 45 min on hotplate). (a2) Coated wafer exposed to UV light through a photo mask. (a3) Post exposure bake (65 °C for 1 min, 95 °C for 5 min on hotplate). (a4) SU8 developed in SU8 developer for 5–8 min to get master mould with holes. Silanize with Trichloro(1H,1H,2H,2H-perfluorooctyl) silane for 10 min in vacuum. (b1) AUS orange dye (20% by weight) and PDMS (Sylgard 184, 10:1 base to curing agent ratio) mixture poured on master mould, (b2) Degas in vacuum desiccator, (b3) Remove excess colored PDMS, (b4) pour clear PDMS (10:1) and cure at 60 °C on hotplate for 1 h and at 100 °C in a convection oven for 9 h, (b5) Peel off the cured PDMS device after cooling to room temperature and cure again at 100 °C in oven for 9 h to ensure complete cross-linking. (c) Top view of non-colored PDMS micropillars (d) Side view of non-colored PDMS micropillars. (e) Top view of colored PDMS micropillars. (f) Colored PDMS micropillar device on microscope slide.