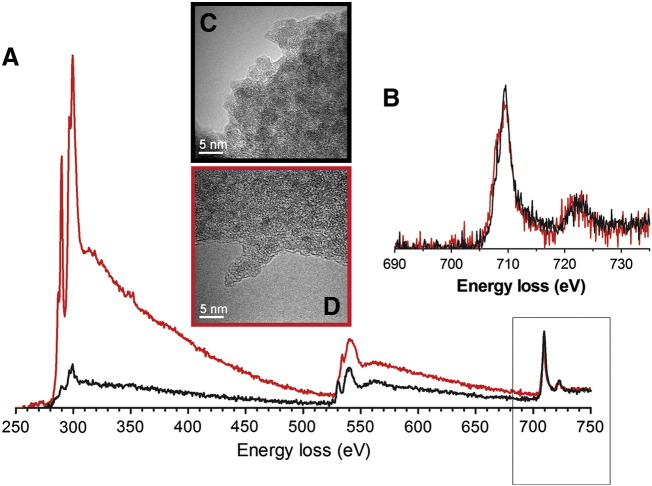

Figure 4.

Electron microscopy-based characterization of tartrate-modified ferrihydrite (red) against synthetic ferrihydrite (black). (A) Background-stripped electron energy-loss spectra (EELS) for the combined C K-edges (285 eV), Ca L2,3-edges (346 eV), O K-edges (530 eV) and Fe L2,3-edges (709.5 eV) normalized to the continuum intensity post the Fe L2,3-edges. (B) individual background-stripped Fe L2,3-edges. The unaltered shape of the Fe L2,3-edges indicates that the Fe−(O, OH)6 octahedra remain relatively unchanged after tartrate modification: i.e. the material remains Fe(III). (C and D) Bright-field transmission electron microscopy (TEM) images of synthetic ferrihydrite (C) and tartrate-modified ferrihydrite (D) agglomerates suspended over holes in the TEM support film (see supplementary methods for details of specimen preparation). Diffraction contrast from individual crystallites produces dark regions in the images, the size of which confirms the reduced crystallite size of the modified material. Synthetic ferrihydrite was precipitated from an Fe(III) chloride solution and tartrate-modified ferrihydrite from an Fe(III) chloride solution in the presence of tartrate and adipate buffer (Fe/tartrate/adipate = 1:0.5:0.5).