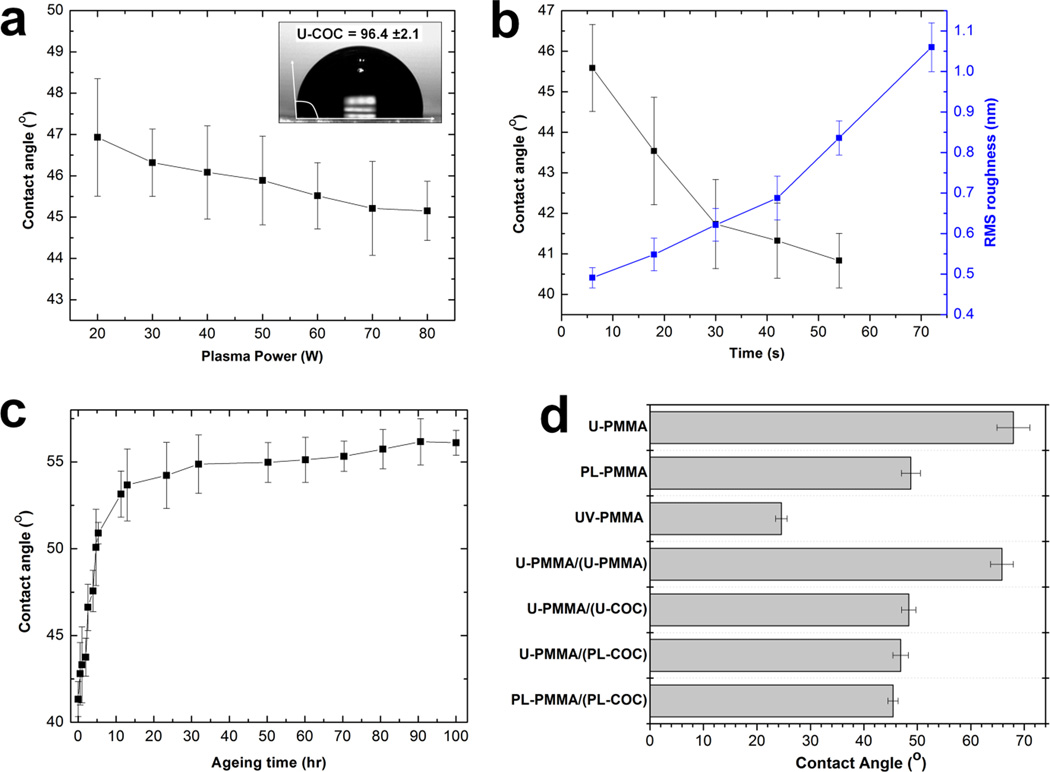

Figure 2.

(a) Plot of the variation of the water contact angle with the RF power for an oxygen plasma at 10 sccm gas flow rate and a constant exposure time of 10 s. (b) Plot of the relationship between the water contact angle (black trace) and the RMS roughness (blue trace) versus the plasma exposure time at 50 W for 10 sccm O2 gas flow rate. (c) Effect of ageing under room temperature conditions on the water contact angle of a plasma treated COC cover plate for plasma treatment of 50 W at 30 s under 10 sccm oxygen flow rate. (d) Water contact angle measurements of a PMMA substrate under different surface modification conditions with and without the COC cover plate. ‘U-PMMA’ is an untreated PMMA substrate; PL-PMMA is a plasma treated PMMA substrate; UV-PMMA is UV/O3-activated PMMA substrate; U-PMMA/(U-PMMA) is untreated PMMA substrate UV/O3-activated through an untreated PMMA cover plate; U-PMMA/(U-COC) is an untreated PMMA substrate UV-activated through an untreated COC cover plate; U-PMMA/(PL-COC) is untreated PMMA substrate UV-activated through a plasma treated COC cover plate; and PL-PMMA/(PL-COC) is plasma treated PMMA substrate UV/O3-activated through a plasma treated COC cover plate.