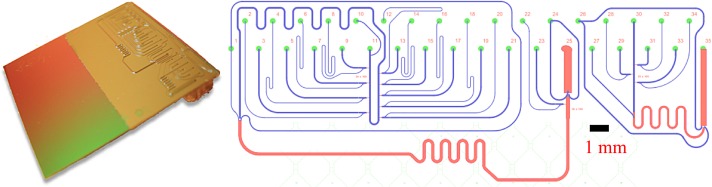

FIG. 2.

Microfluidic chip for parallel nl droplet generation and injection mixing. Left: Fully assembled droplet processor on silicon with micro-molded three-layer PDMS fluidics and backside interconnection. Right: Dynamic DoD final microfluidic chip design. Inlets 2, 4, 6, 8, 14, 16, 18, 20, and 22 are used for reactants or markers and inlets 1, 10, 11, and 24 for carrier fluids, allowing for adding different surfactants or changing droplet spacing. Outlet 25 transports the created droplets into an output FEP (fluorinated ethylene propylene)-tube. All other inlets are used as backpressure ports for the droplet creation. Dimensions of nozzles (first microfluidic layer): length 80 or 100 μm, width 30 μm, and height 2 μm; second layer (height 45 μm, blue color) for I/O channels; third layer (height 115 μm, red color) for short downstream meander and output channel. The separate structure on the far right is an additional test-structure.