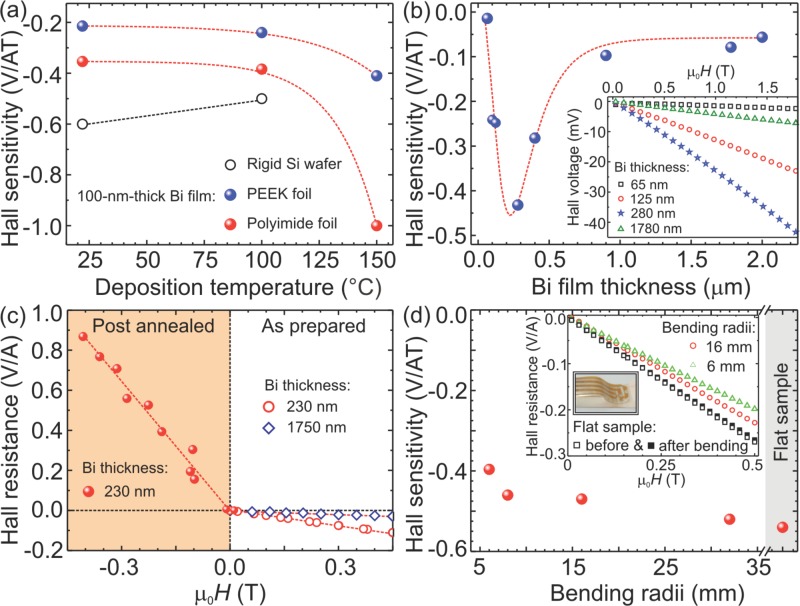

Figure 3.

Performance of the flexible Hall sensors. a) Hall sensitivity of the 100-nm-thick Bi film grown onto flexible PEEK and polyimide foils measured on the samples prepared at different temperatures. Respective data for the samples prepared on rigid Si wafers is shown for comparison. b) Impact of the Bi film thickness on the Hall sensitivity for the sensors prepared at RT on PEEK foils. The inset shows the change of the Hall voltage with a magnetic flux density of the sensor elements as a function of the Bi film thickness. The measurement was carried out with a supply current of 50 mA. c) Change of the Hall resistance with magnetic flux density measured of the 230-nm-thick Bi film prepared on a polyimide foil. A comparison of the Hall characteristics of the as-prepared and post-annealed samples is shown in the right and left panels, respectively. Post-annealing was performed at 250 °C for 3 h. Right panel shows the Hall resistance of the samples of different thickness. Dashed lines are a guide to the eye. d) Variation of the Hall resistance of flexible sensors upon bending. The sensor consists of a 200-nm-thick Bi film prepared at RT on a polyimide foil and is applied to different sample holders with defined curvatures (inset). The change of the sensitivity of the sensor with bending radii is shown as an inset graph.