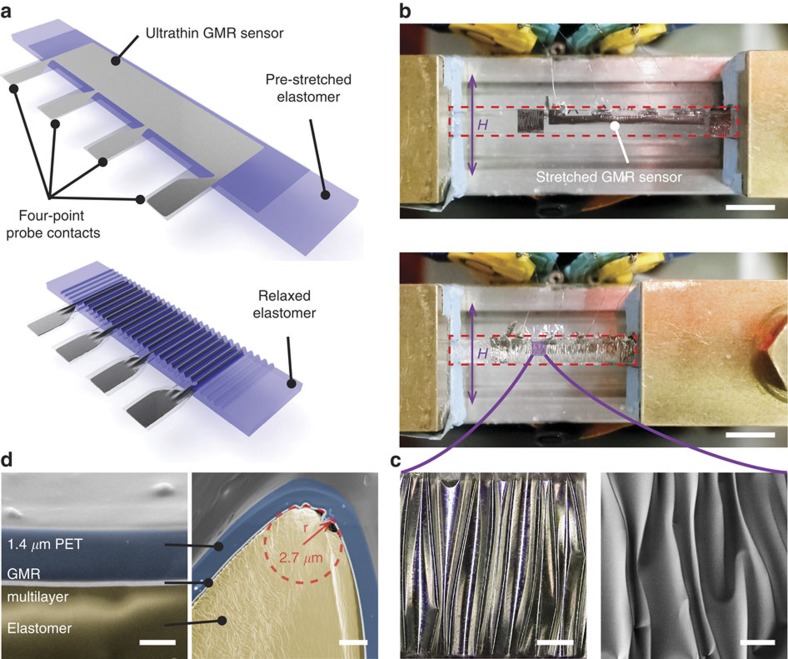

Figure 2. Stretchable GMR sensors.

(a) Illustration of stretchable magnetoelectronics. A multilayer GMR element on ultrathin PET is laminated face down onto a prestretched stripe of sticky rubber tape. Four contact pads are reaching beyond the tape (top). Relaxing the elastomer results in out-of-plane wrinkling of the sensor foil and enables re-stretching (bottom). (b) Py/Cu second maximum sample mounted to the in situ stretching stage fully elongated (top) and compressed by 50% (bottom). The pink arrow indicates the axis of the applied magnetic field. Scale bars, 5 mm. (c) Optical microscopy (scale bar, 200 μm) and SEM. (scale bar, 100 μm) top-view images reveal the wrinkle structure of the sensor surface in its compressed state. (d) Cross-sectional SEM images of the sensor foil laminated to the rubber tape. The GMR nanomembrane is encapsulated between the ultrathin PET and the stretchable adhesive tape. Some parts of the magnetoresistive foil on the tip of the buckles are bent into radii of curvature of <3 μm (right). Scale bars, 1 μm (left), 2 μm (right).