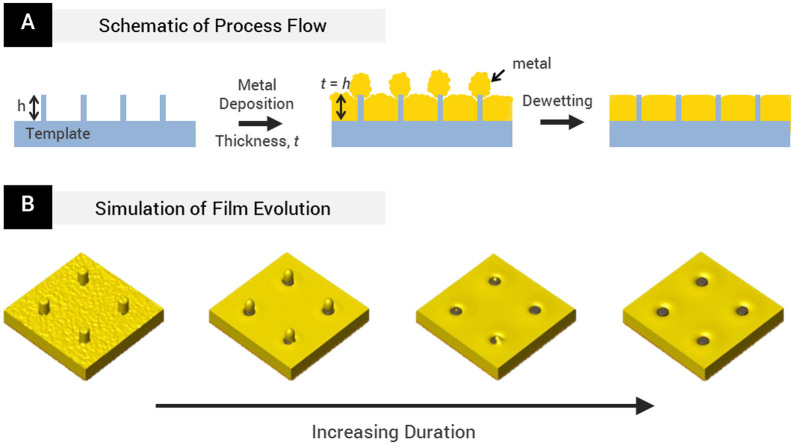

Figure 1.

(A) Schematic illustrating the fabrication process. A template consisting of nanopillars with height, h, is used. Next, metal of thickness, t, equal to h, is deposited via electron beam deposition. Finally, solid-state dewetting is induced at low temperature (<400°C). As a result of capillary-assisted diffusion, the metal caps on top of the nanopillars dewet away from the nanopillars into the surrounding metal film, revealing nanoapertures. (B) Simulated time-lapse view of the dewetting process obtained using a three-dimensional phase field model. The metal caps atop the nanopillars ball up and form joints with the surrounding film. With increasing duration, the metal caps are drawn away from the tops of the nanopillars into the surrounding film.