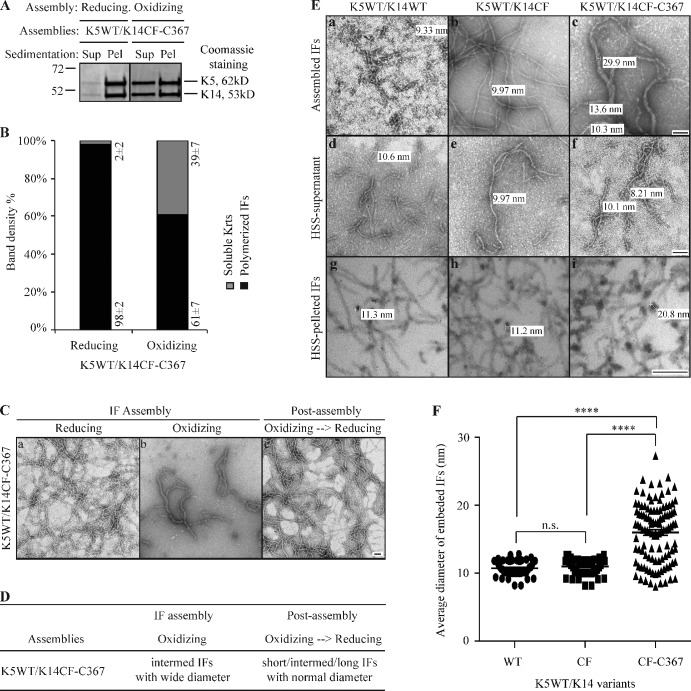

Figure 5.

Formation of K14CF-C367–mediated disulfide bonds yields abnormal IFs with wide diameters in vitro. (A) High-speed sedimentation assay (150,000 g, 30 min) followed by SDS-PAGE analysis of supernatant (Sup) and pellet (Pel) fractions. K14CF-C367 was coassembled with K5WT under both reducing and oxidizing buffer conditions. (B) Quantitation of filament assembly efficiency using densitometry-based analysis of the corresponding fractions in A. Data are presented as mean ± SD from three independent experiments. (C) Negative staining and transmission electron microscopy reveals the abnormal morphology of K14CF-C367–containing filaments under oxidizing buffer conditions, which can be restored upon exposure to a reducing environment at the post-assembly stage. Bar, 100 nm. (D) Summary of in vitro assembly data for K5/K14CF-C367 under various buffer conditions. Short IFs, 200–500 nm; intermed IFs, 500–1,000 nm; long IFs, >1 µm; normal diameter, 8–12 nm; wide diameter, >13 nm. (E) Morphology of WT, cysteine-free (CF), and CF-C367 of K14-containing filaments assembled under oxidizing buffer conditions. The top row shows examples of negatively stained intact assemblies upon completion of the reaction, while the middle and bottom row are examples, respectively, of negatively stained supernatant fractions after a high-speed sedimentation assay and cross sections of epoxy resin-embedded pellet fractions. HSS, high-speed sedimentation. Bar, 100 nm. (F) Measurements of diameters of cross-sectioned filaments corresponding to HSS-pelleted IFs (bottom row in E). More than 50 cross sectioned IFs were measured for K14WT and K14CF, and >100 cross sectioned IFs were measured for K14CF-C367. P < 0.0001 (****).