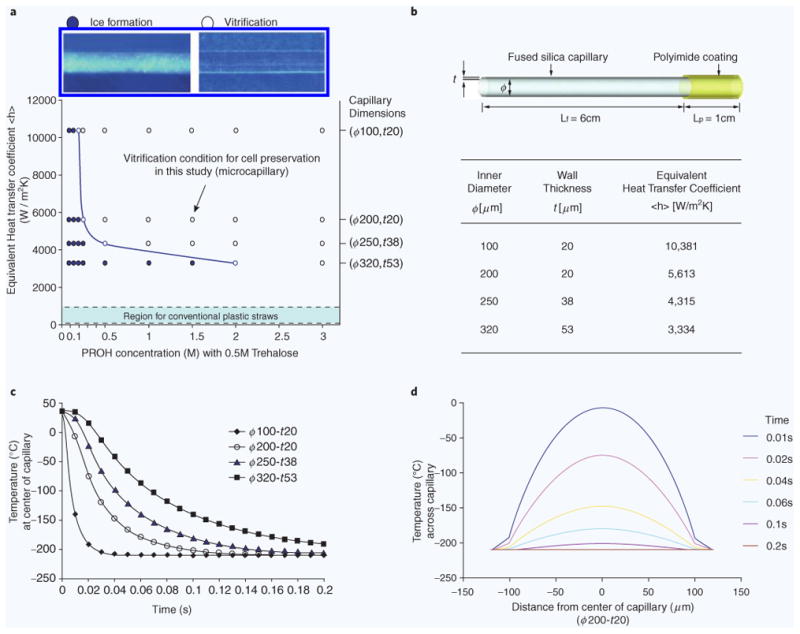

Figure 1.

Evaluation of a fused silica microcapillary microcapillary as a tool for vitrification. (a) Map showing the heat transfer and cyoprotectant requirements for vitrification. The line indicated the relationship between the varying dimensions of microcapillary and the levels of CPAs, required to achieve “ice-free” conditions during freezing. Experimentally tested conditions are indicated as dots. (b) Equivalent heat transfer coefficients were calculated based on the inner diameter (ϕ) and wall thickness (t) of the microcapillaries, and used as a single parameter to evaluate the heat transfer rates. (c) The temperatures inside capillary filled with media decreases as the dimension of microcapillary increases — heat transfer analysis using computer simulations (COMSOL). (d) Estimated temperature profiles across a cylindrical model of a 200 μm(ϕ)−20 μm(t) capillary during freezing by plunging the capillary into slush nitrogen (−210 °C).