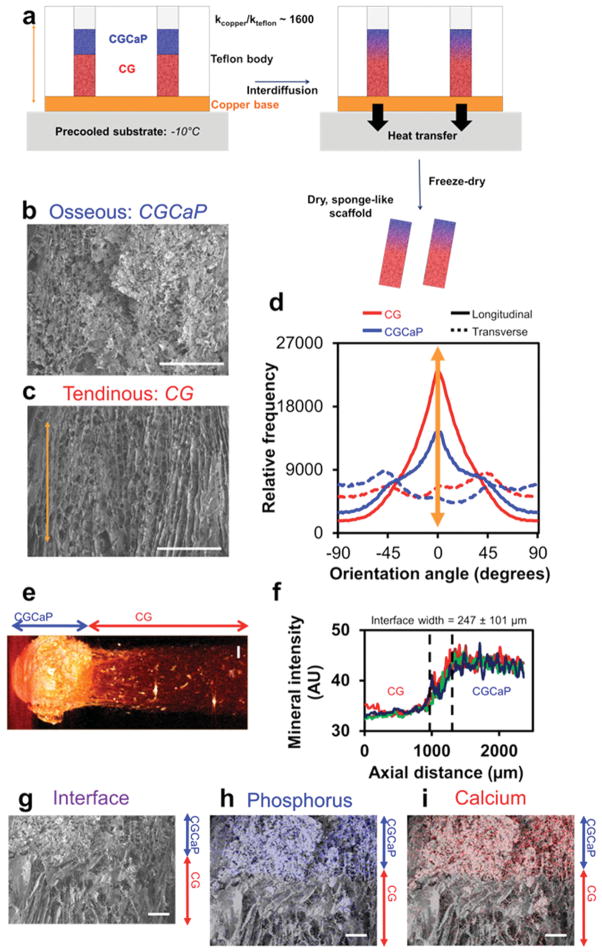

Figure 1.

Microarchitecture and calcium phosphate content of multi-compartment TBJ scaffolds. a) Schematic of approach to make multicompartment osteotendinous scaffolds with distinct regions of pore anisotropy and mineral content. The approach combined directional solidification to produce aligned pores with liquid phase co-synthesis to integrate the nonmineralized CG (red) and mineralized CGCaP (blue) compartments together into a single construct. Scanning electron micrographs indicate b) relatively isotropic pores in the mineralized osseous (CGCaP) region and c) highly aligned pores in the non-mineralized tendinous (CG) region. Scale bars: 200 μm. d) OrientationJ analysis of pore alignment demonstrated that pores were longitudinally aligned in the tendinous compartment, but more randomly aligned in the corresponding osseous compartment. e) Micro-CT image of osteotendinous scaffold. Scale bar: 1 mm. f) Using differences in the intensity of the mineralized versus nonmineralized compartments, the interface width was calculated to be approximately 247 ± 101 μm. g) continuity of collagen fibers at the interface between compartments was demonstrated with energy-dispersive X-ray spectroscopy analysis revealing localization of h) calcium and i) phosphorus content primarily in the mineralized osseous region of the scaffold. Scale bars: 200 μm.