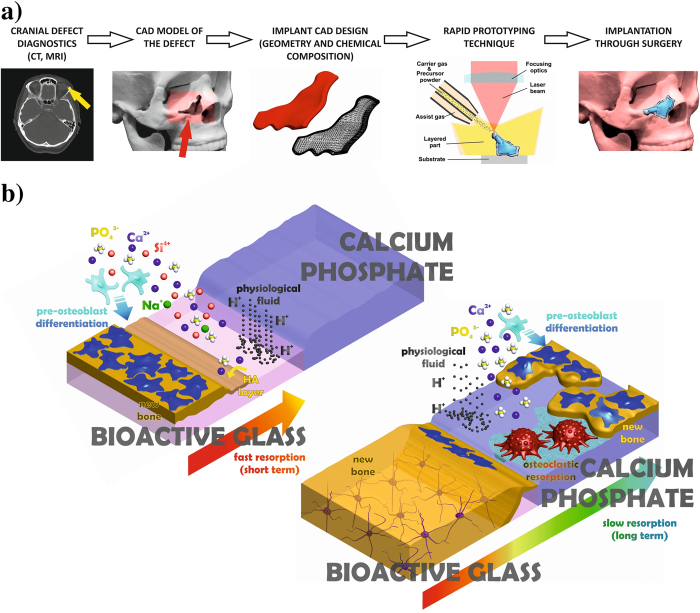

Figure 1.

Schematic illustration of implant tailored fabrication from defect diagnostics, and of the approach followed in this work to attain a progressively resorbed material. (a) Computerized imaging techniques provide three-dimensional data of the bone defect, which are employed to design a computer model of the required implant, afterward fabricated by a rapid prototyping technique. (b) The outer bioactive glass (BG) layer (upper left) of the implant is resorbed within an initial stage by the physiological fluid, favoring the precipitation of an osteoconductive HA layer and the differentiation of osteoblast precursors required for intensive bone formation. Subsequently, the inner multiphasic CaP is slowly resorbed by mediation of osteoclasts and physiological fluid, releasing chemical species that promote bone ingrowth and providing stability at long term.