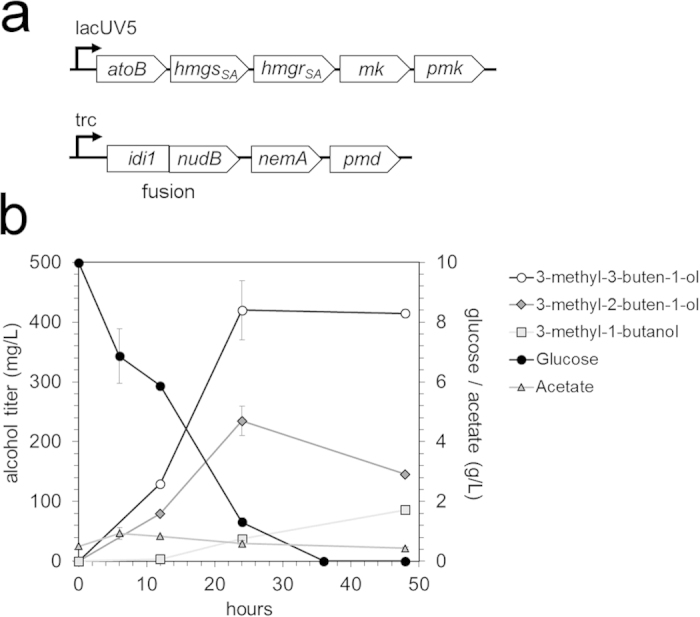

Figure 4. Engineering to produce mixed alcohols.

(a) Plasmid architecture. To produce 3-methyl-2-buten-1-ol and 3-methyl-1-butanol in addition to 3-methyl-3-buten-1-ol, plasmid 1 from strain KG1 (CmR, p15A ori) was paired with a mixed alcohol production plasmid (AmpR, pBR322 ori) encoding an Idi1~NudB fusion protein and a reductase (NemA)12 to create strain KG8. (b) Mixed alcohol production in strain KG8. A fermentation time-course revealed that strain KG8 produced three C5 alcohols. By 48 hours, strain KG8 produced over 400 mg/L of 3-methyl-1-buten-1-ol, 150 mg/L of 3-methyl-2-buten-1-ol, and 100 mg/L of 3-methyl-1-butanol. All glucose was consumed by 36 hours, and acetate secretion was minimal. Error bars represent standard deviation (n = 3).