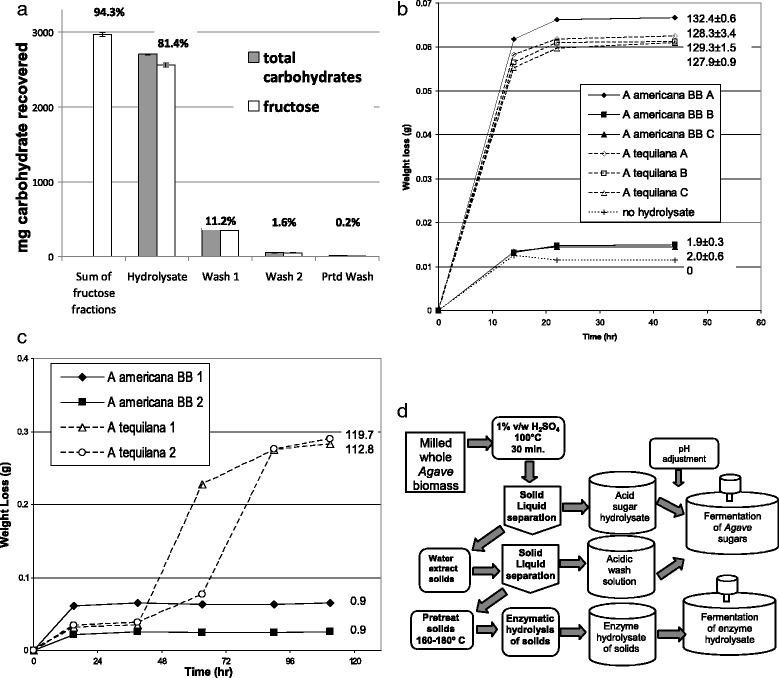

Fig. 3.

Development of a two stage conversion procedure for improved conversion of Agave carbohydrates. a Shown are fructose and total carbohydrate levels after a mild acidic hydrolysis process of a blend of 3 g each cellulose and inulin in triplicates. The total milligrams of fructose or total carbohydrates liberated are shown with standard deviation. Inserted number: percentage of fructose recovered in relevant fraction. Fructose percent data was corrected for hydrolysis weight gain. b Impact of acid hydrolysis of two Agave biomass sources with and without inulinase on SHF conversion to ethanol. All samples received acid hydrolysis before enzymatic hydrolysis with or without inulinase. A Room temperature acid hydrolysis with added inulinase. B High temperature acid hydrolysis without added inulinase. C Room temperature acid hydrolysis without added inulinase. Weight loss of individual duplicate 35 °C fermentations is shown. c Impact of high temperature acid hydrolysis of two Agave biomass sources before SSF enzymatic hydrolysis and fermentation with and without inulinase. Weight loss of individual duplicate 35 °C fermentations is shown. Solid line A. americana BB biomass, dotted line A. tequilana biomass. Numbers in (b) and (c) are ethanol mg/g dry biomass with standard deviation. d Two-step Agave sugar extraction and fermentation procedure using mild acid hydrolysis, solid washing, and acidic pretreatment of solids followed by enzymatic hydrolysis yielding two fermentation sugar streams