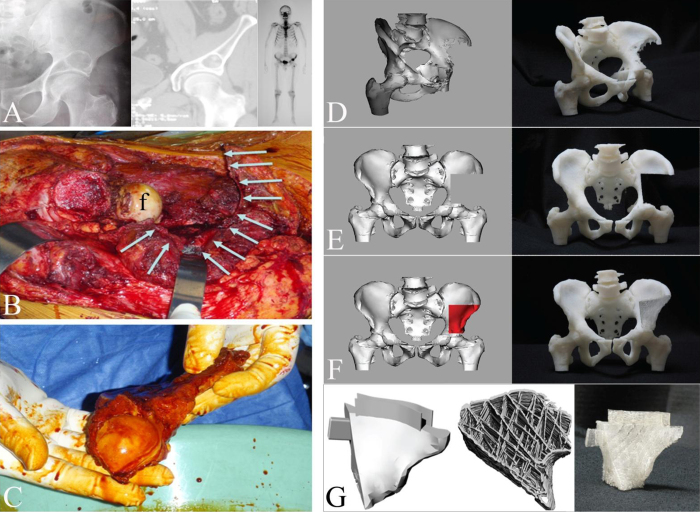

Figure 9.

Clinical case of a 52 year old man with a malignant bone tumour above his left hip. (A) X ray and computed tomogram showing mixed lytic sclerotic lesion above the left acetabulum, Technitium-MDP bone scan demonstrating focal area of increased tracer uptake within the tumour. (B) Tumour resection leaving a large pelvic defect (white arrows), f=femoral head. (C) Resected specimen including upper part of acetabulum (Clinical images: P.F.C.). The surgical resection creates a large bone defect in the pelvis that necessitates the use of autograft/allograft bone material and/or orthopaedic implants to reconstitute the pelvic anatomy. A novel approach (D-G) could be the use of custom made porous bone tissue engineering scaffolds fabricated via Computer Aided Design (CAD) to regenerate such defects: Data obtained from high-resolution CT can be used to create a 3D computer-aided designed (CAD) model of the patient's pelvis by additive manufacturing (D). This model can be used by the orthopaedic surgeon to indicate osteotomy planes to achieve tumour free margins, after which, after which the CAD model is virtually resected (E). A custom made scaffold to fit the defined defect is then created by mirroring the healthy side of the pelvis, adjusting the size of the scaffold accordingly and fabricating the scaffold from the virtual model using AM techniques (F). Flanges, intramedullary pegs and other details can be added to the porous scaffold structure to facilitate surgical fixation and to enhance its primary stability after implantation (G). Images D-G reproduced with permission from (246), © The authors