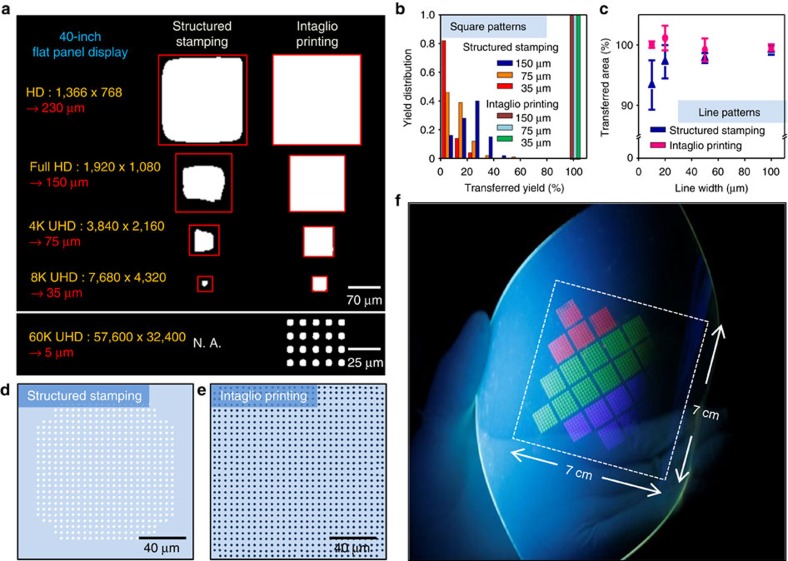

Figure 2. Experimental and theoretical analysis of the intaglio transfer printing.

(a) Pattern size scaling in the structured stamping (left) and intaglio transfer printing (right). QD transfer yields of the structured stamping dramatically decrease especially in high resolutions, while those of the intaglio printing approach ∼100% in all design rules. (b) Distribution of transfer printing yields at different pattern sizes (150, 75 and 45 μm). The transfer printing yield for the structured stamping dramatically decreases with the pattern size, while that of intaglio printing maintains ∼100%. Detailed results are shown in Supplementary Fig. 2. (c) Percentile proportion of the transferred QD line pattern area to the original pattern area. As the line width decreases from 100 to 10 μm, the structured stamping yield decreases, while intaglio printing maintains ∼100%. Detailed results are shown in Supplementary Fig. 4. (d,e) FEM simulations of the transferred area of the rectangular pattern (size: 150 × 150 μm) for the structured stamping (d) and intaglio printing (e). (f) PL image of a large-area QD dot array (7 × 7 cm) patterned by repeated aligned intaglio transfer printing on a flexible polyethylene terephthalate substrate.