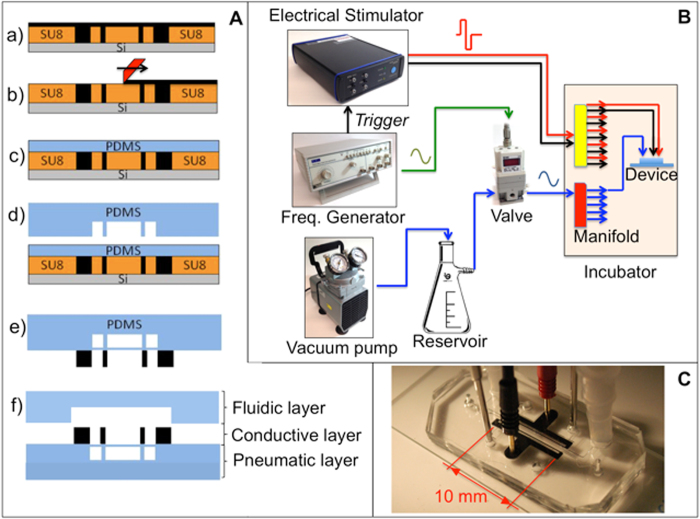

Figure 2. Device fabrication and control system setup.

(A) Device fabrication steps. (a) Casting of conductive mixture (PDMS + multiwalled CNTs) on top of the silicon wafer mold; b) scraping the excess material from the wafer surface and temperature curing; (c) spin coating the 100 μm PDMS layer to obtain a deformable membrane; (d) bonding the pneumatic layer on top of the membrane; (e) demolding the assembled pneumatic and conductive layers; (f) bonding the cover layer in order to seal the fluidic channels. Dimensions are not drawn to scale. (B) Schematic of the control system. Alternated vacuum is obtained through an electronic valve controlled by a frequency generator which has the function to trigger the electrical stimulator as well. Inside the incubator, the vacuum and electrical lines are split to provide stimulation to multiple devices in parallel. (C) Photo of the final assembled device, including electrical connections and tubing for vacuum control.