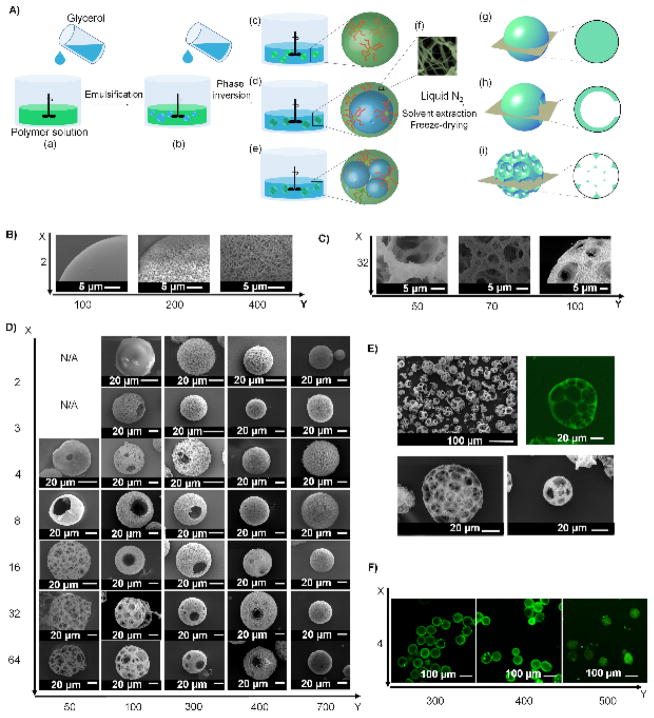

Figure 1. (A) An illustration of the combination of emulsification and thermally-induced phase separation to fabricate nano- and micro-structured spheres.

(a, b) Glycerol is slowly poured into a stirred polymer solution. (c–e) As the amount of the added glycerol increases, catastrophic phase inversion occurs, generating three types of emulsions: (c) a single emulsion (simple polymer droplets); (d) a double emulsion (one inner droplet of glycerol inside one polymer droplet); and (e) an emulsion with multiple inner droplets of glycerol inside one polymer droplet (referred as “multiple emulsion” hereafter). (f) Emulsions are quenched in liquid nitrogen to induce phase separation on the nanometre scale. Upon solvent/glycerol extraction and freeze-drying, (g) the single emulsions form non-hollow microspheres; (h) the double emulsions form hollow microspheres; and (i) the multiple emulsions form spongy microspheres. (B–F) Structural characterization of microspheres fabricated from SS-PLLA of different X and Y. B–D) SEM micrographs of microspheres fabricated from (B) 2-arm PLLAs with Y= 100, 200 and 400. Scale bars: 5 μm; (C) 32-arm PLLAs with Y= 50, 70 and 100. Scale bars: 5 μm; (D) SS-PLLAs of different X and Y, showing the structural transition process as X and Y changes. Scale bars: 20 μm. (E) SEM and cross-sectional confocal images of microspheres formed from 32-arm PLLA-100. Scale bars: 100 μm in top left panel and 20 μm in the rest of the panels; (F) Cross-sectional confocal images of microspheres fabricated from 4-arm PLLAs with Y= 300, 400 and 500. Scale bars: 100 μm.