Table 3.

Microflow amide bond formation with various substrates.

| Entry | Structure of | Cond. | Yield [%] | |

|---|---|---|---|---|

| desired product | (desired) | (epimer) | ||

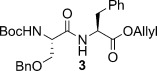

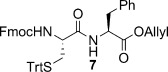

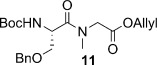

| 1 |  |

flow A[a] batch[d] | 92 57 | 1 2 |

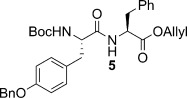

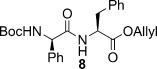

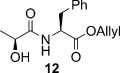

| 2 |  |

flow B[b] batch[d] | quant. 40 | <1 <1 |

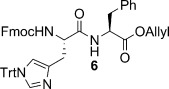

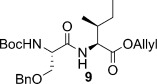

| 3 |  |

flow B[b] batch[d] | 92 75 | 2 17 |

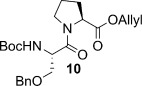

| 4 |  |

flow A[a] batch[d] | 94 71 | <1 1 |

| 5 |  |

flow C[c] batch[d] | 97 74 | 3 18 |

| 6 |  |

flow B[b] batch[d] | 89 47 | <1 1 |

| 7 |  |

flow A[a] batch[d] | 80 58 | <1 1 |

| 8 |  |

flow A[a] batch[d] | 74 53 | <1 <1 |

| 9 |  |

flow A[a] batch[d] | 98 <28 | <1 |

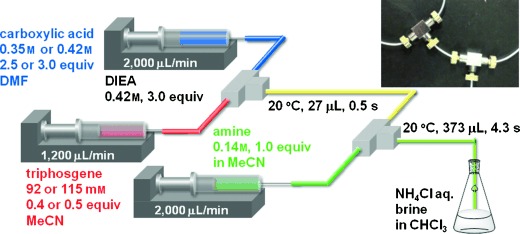

Carboxylic acid: 2.5 equiv, triphosgene: 0.4 equiv.

Carboxylic acid: 3.0 equiv, triphosgene: 0.5 equiv.

Carboxylic acid: 2.5 equiv, triphosgene: 0.4 equiv, DIEA: 2.5 equiv, solvent A: MeCN, reaction temperature: 10 °C.

Reaction time for the activation of carboxylic acid and the amidation: 30 s. Fmoc=9-fluorenylmethyloxycarbonyl.