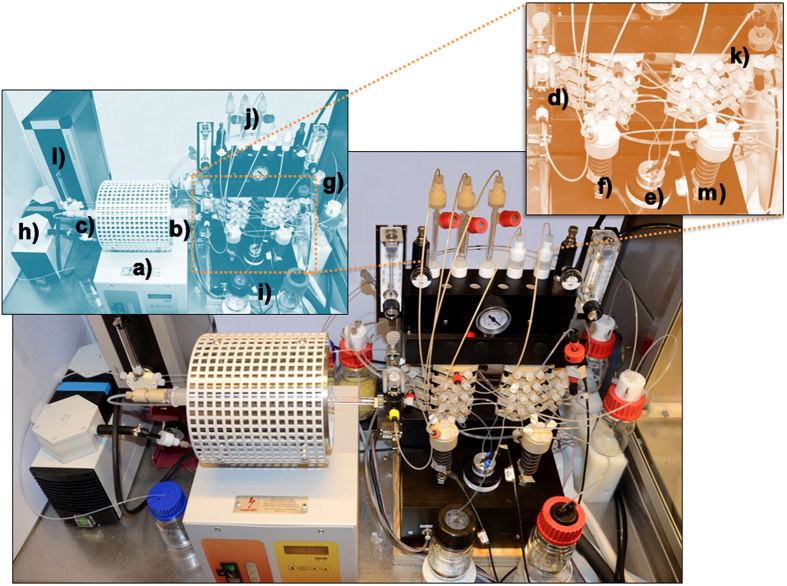

Figure 2. The automated process platform is set up inside a glovebox.

The platform components are labelled in the upper boxes. The platform consists of (a) a tube furnace for At-211 dry distillation at 700 °C; (b) a quartz glass oven; the oven is fitted with a flow-through quartz glass stopper (c,d) three-way valve for capillary elution; (e) a cryotrap for astatine capture; (f) a reaction vial for radiolabelling compounds with At-211; (g) astatine capture traps (expansion trap, a sulphite scrub container, and another expansion trap); (h) a vacuum pump with a capacity of 10 l/min; (i,j) buffer and reagent storage containers; (k) an on-line purification column (size exclusion) with an attached silicon PIN diode detector; (l) a syringe dispenser, and (m) a product vial.