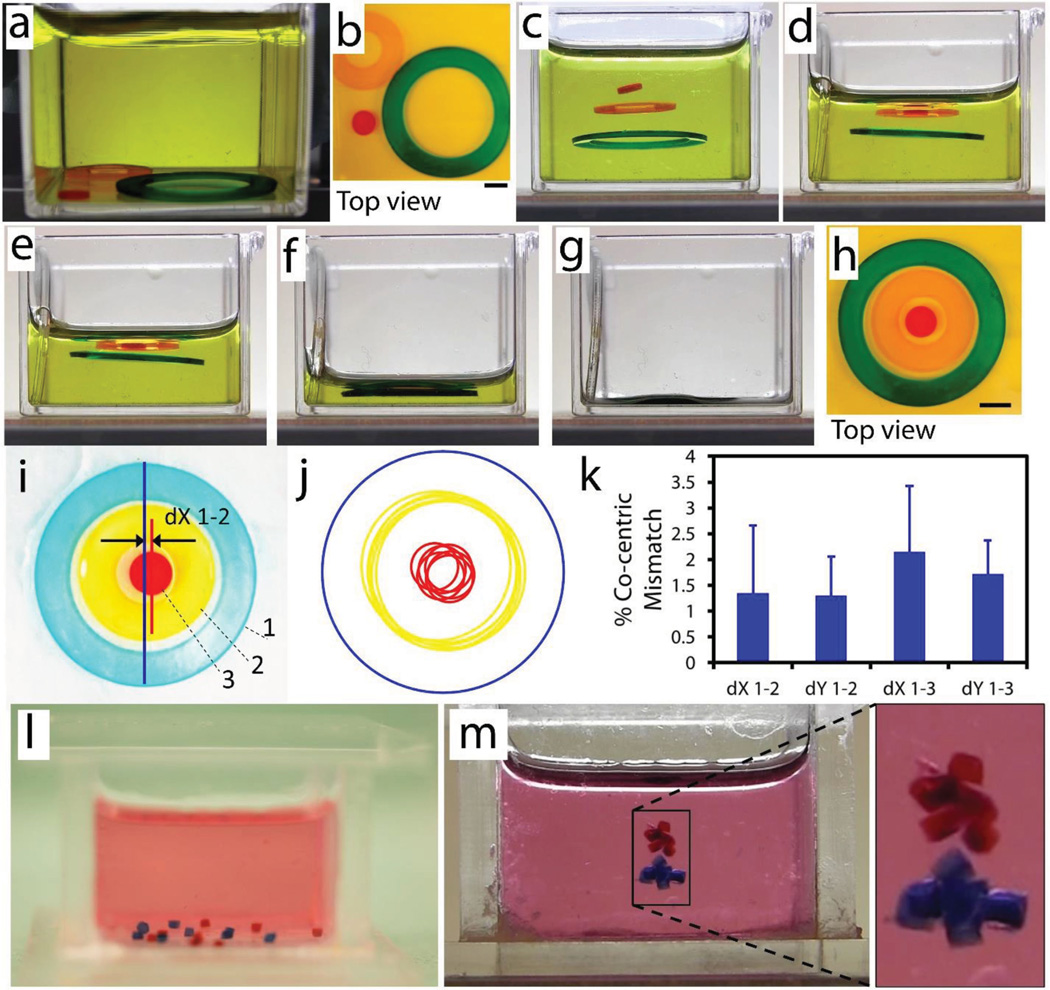

Figure 4.

Levitational self-assembly of soft microcomponents. a–h) Concentric assembly of two hollow-disk and a solid-disk PEG gels (Supporting Information, Movie 3). a,b) Gels were randomly placed at the bottom of reservoir before being placed into a magnetic setup composed of two NdFeB magnets with like poles facing each other. c) Upon placement of reservoir into the magnetic setup, gels were aligned horizontally at the center of magnets due to minimum magnetic field strength and equilibrated vertically at different heights due to differences in densities among gel groups. Differences in gel densities were achieved by adding different amounts of polymer into precursor solution (red = 15% w/v, orange = 20% w/v, green = 50% w/v). d–g) Draining of the paramagnetic media from the reservoir decreased the height of air–liquid meniscus and caused a concentric deposition of gels. All scale bars are 1 mm. h) Final shape of assembled gels. i) Image of a concentric assembly with numerated gels. j) Mathematical equations of each circle were obtained by randomly picking three points at the outer circumferences of gels. Then, shapes were recreated using these mathematical equations, and plotted on top of each other while keeping the location of outer circle same. k) Concentric mismatches were calculated by finding the distances among centroids of two groups: 1–2) outer circle and middle gel, and 1–3) outer circle and inner gel. Results showed that concentric assembly has a high repeatability with around 2% mismatch (n = 6). l,m) Selective levitational assembly of two types of PEG hydrogels (red = 20% w/v, blue = 50% w/v) (Supporting Information, Movie 4). l) Hydrogels at the bottom of the reservoir before being placed into the magnetic setup. m) Blue hydrogels and red hydrogels formed assemblies at different levels due to difference in their polymer concentration.