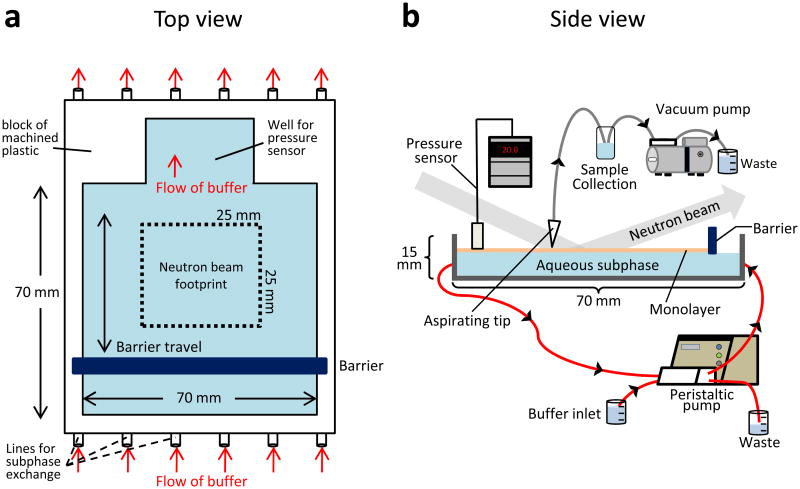

Figure 1.

Diagram of the Langmuir trough used for labeling experiments from the top (A) and the side (B). This design was adapted from the trough used for neutron reflection studies29 where the neutron beam footprint was a square of 25 mm on each side. The areas in blue represent the buffered aqueous subphase (18 mL total volume) upon which the monolayer (orange in panel B) floats. After lipid is spread on the subphase, a motor-driven barrier compresses the monolayer to a set lipid packing density as monitored with the pressure sensor. The computer control system (not shown) integrates the pressure sensor and barrier position and can be set to move the barrier to maintain constant pressure, if desired. Protein samples are injected underneath the monolayer after it is in place. Red arrows indicate the flow of buffer through the trough, driven by the peristaltic pump, during subphase exchange and deuterium labeling. A vacuum pump is used to aspirate labeled samples directly from the monolayer into a cold collection tube.