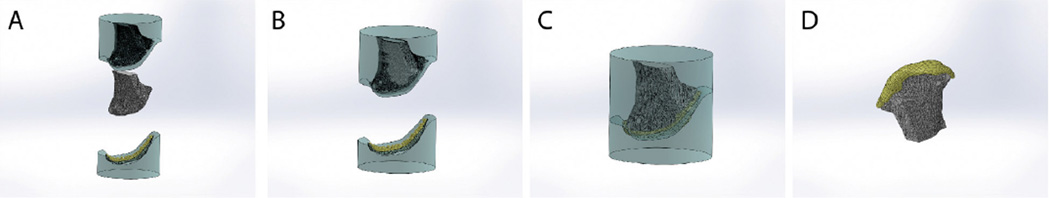

Figure 2. Fabrication of osteochondral grafts.

A Silicone mold was made in two pieces, and the CMBs were placed at the articular side. B An anatomically shaped scaffold machined by image-guided processing of native decellularized bone matrix is then placed into the other side of the mold. C The two-piece mold is fused together, to press the CMBs into a desired shape of an articular surface on the scaffold. D A compact layer of CMBs is formed at the surface of decellularized bone which can also be seeded by BMSCs. The resulting construct is then cultured in a matching, anatomically shaped bioreactor chamber. Image reproduced with permission from Bhumiratana et al., PNAS 111, 6940, 2014) (16).