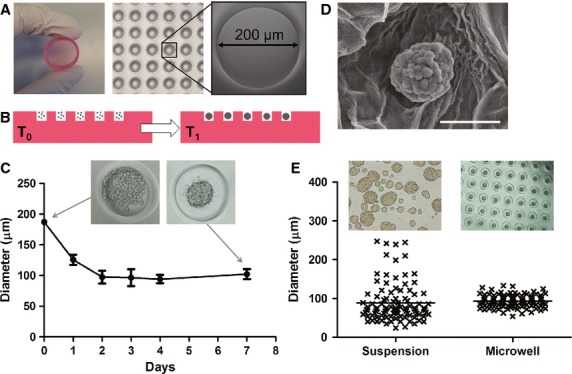

Figure 2.

Fabrication and validation of a microwell platform for controlled production of uniformly sized aggregates. (A) Agarose microwell chip containing 2865 non-adherent wells with a diameter of 200 μm. (B) Schematic representation of controlled cell aggregation in agarose microwell chips. Single cells are seeded in suspension onto agarose microwell chips and briefly centrifuged to allow the cells to settle down in the microwells (T0). In time, cells assemble and stable cell clusters are formed (T1). (C) INS-1E cell aggregate formation in agarose microwells. Single INS-1E cells aggregate in the first 2 days of culture and form stable aggregates that were maintained up to 7 days of culture. (D) SEM image of an INS-1E cell aggregate that was embedded in agarose gel; scale bar = 50 μm. (E) The microwell platform generates uniformly sized INS-1E cell aggregates with less variability (SD = 16) compared to conventional suspension culture (SD = 49; n = 100).