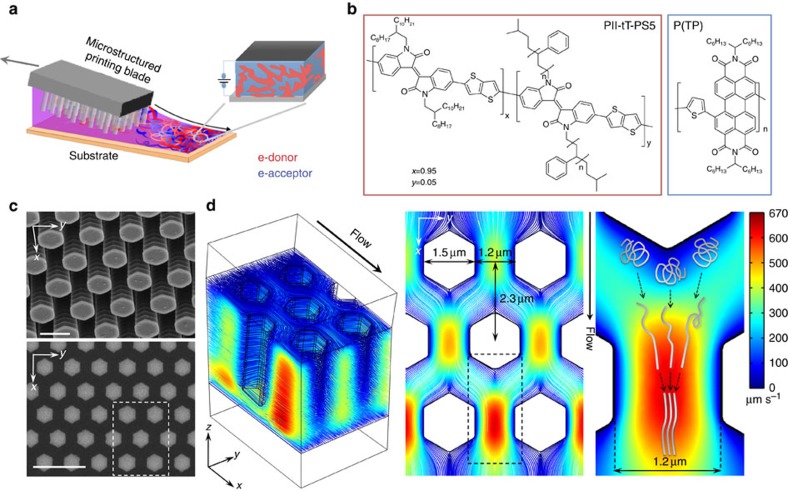

Figure 1. FLUENCE for controlling microphase separation of printed all-polymer solar cells.

FLUENCE stands for ‘fluid-enhanced crystal engineering'. (a) Schematic of the FLUENCE method implemented on the solution shearing platform. (b) Schematic of the microphase-separated morphology in bulk heterojunction solar cell and the molecular structures of the electron-donor and electron-acceptor polymers used in this study. (c) Scanning electron microscope images of the microstructured printing blade, scale bar 2 μm (top), 5 μm (bottom). The white dotted line indicates the size of the simulation box in the xy plane. (d) Finite element simulation results (stream-line representation) of the flow field between the microstructured printing blade and the substrate. The simulated printing speed is 50 μm s−1. The colour scale of the fluid velocity is shown to the right. In this case, the flow is mainly driven by solvent evaporation instead of the printing motion. The cut plane shown (middle image) lies parallel to the substrate, approximately equidistant to the blade and the substrate in the z direction. The hypothesized polymer conformation change, alignment and aggregation/crystallization under extensional and shear flow are depicted in the simulated flow field (right image).