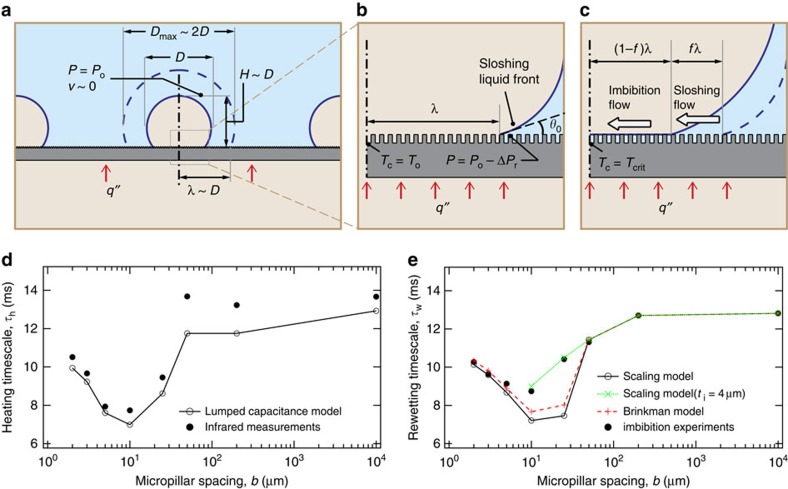

Figure 6. Characteristic timescales for the CHF scaling model.

(a) An idealized spherical vapour mass formed on the boiling surface at CHF. Corresponding to an average vapour mass diameter D, a dry spot of maximum radius λ∼D can form on the boiling surface. (b) At maximum dry spot radius, the initial substrate temperature at the centre of the dry spot is Tc=To. Assuming uniform bubble curvature for θ0=0, the pressure at the sloshing liquid front is equal to the pressure of the comparatively static liquid near the top of the bubble Po minus a surface wetting pressure reduction term (ΔPr) for partially wetting surfaces (θ0>0). (c) The dry spot is rewetted under the combined effect of gravity-induced inward sloshing motion of the surrounding liquid and imbibition of liquid into the surface micro-textures, where f is the fractional length of the dry spot rewetted as a result of the sloshing motion. At CHF, the substrate temperature Tc exceeds the critical dry spot temperature Tcrit before the rewetting liquid front reaches the centre of the dry spot. The heating timescale τh corresponds to the increase in Tc from To to Tcrit, whereas the rewetting timescale τw denotes the time for complete rewetting of the dry spot. (d) Plot of the dry spot heating timescale (τh) versus micropillar spacing b for the micro-textured surfaces at  . The calculated timescale is based on a thermal lumped capacitance model, whereas the experimental timescale is based on the maximum substrate temperature ramp rate obtained from infrared measurements. The value of the critical dry spot superheat is assumed to be Tcrit—To∼12 °C. (e) Plot of the dry spot rewetting timescale (τw) versus micropillar spacing b for the micro-textured surfaces. The calculated timescale is based on the imbibition scaling model, whereas the measured timescale is based on the imbibition experiments (Supplementary Note 5). The contact angle of water on flat silicon was measured to be θ∼30° (see Methods).

. The calculated timescale is based on a thermal lumped capacitance model, whereas the experimental timescale is based on the maximum substrate temperature ramp rate obtained from infrared measurements. The value of the critical dry spot superheat is assumed to be Tcrit—To∼12 °C. (e) Plot of the dry spot rewetting timescale (τw) versus micropillar spacing b for the micro-textured surfaces. The calculated timescale is based on the imbibition scaling model, whereas the measured timescale is based on the imbibition experiments (Supplementary Note 5). The contact angle of water on flat silicon was measured to be θ∼30° (see Methods).