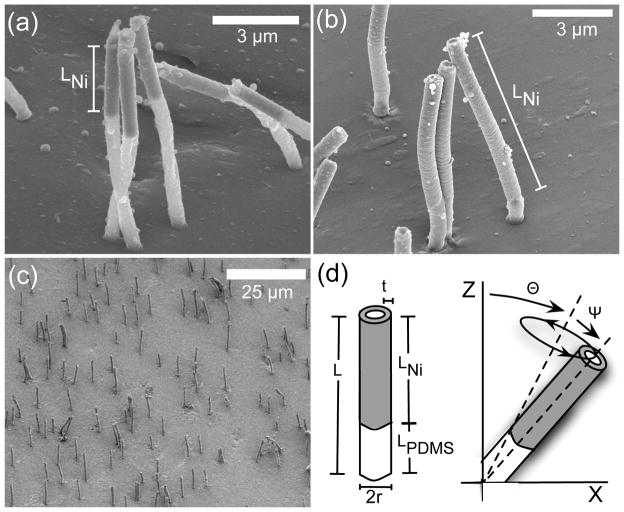

Figure 1.

(a–b) SEM images of core-shell rods taken on a 45° tilted stage show one method of controlling Ni shell size. The amount of electrodeposited Ni is identical, but the pore size in (a) is approximately 660 nm, and in (b) the pore size is 590 nm. Ni shell length is approximately 4 μm in (a) and 9 μm in (b). (c) SEM image of an array of core-shell rods. (d) Diagram describing rod parameters. The length of the rod L is the sum of the length of the Ni tube LNi and the length of the PDMS portion LPDMS. The radius of the rod is r, and the thickness of the Ni tube is defined as t. The tilt angle θ and half cone angle ψ of the rod beat are controlled by the direction and strength of the magnetic field. This asymmetrical beat shape produces a directional fluid flow [32].