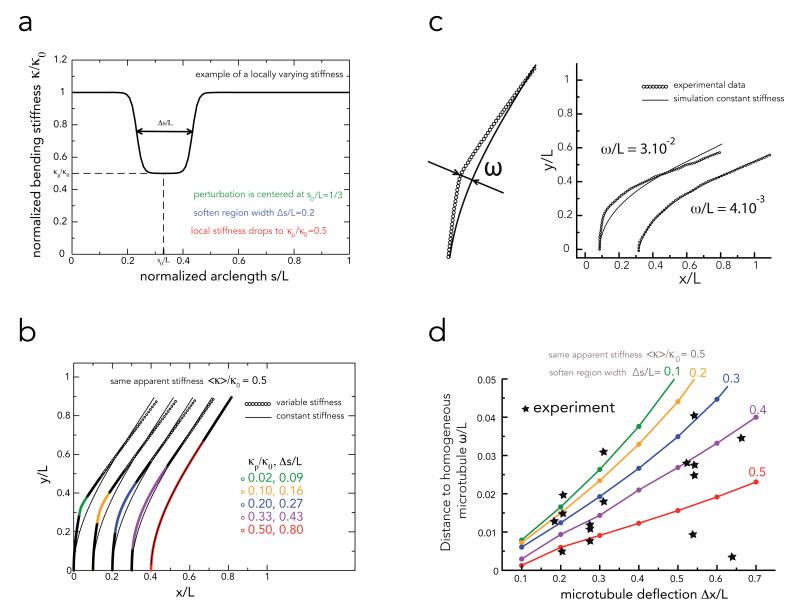

Figure 5. Numerical simulations of microtubule deformations in response to local or global stiffness reduction.

a, This graph represents the parameters used for the simulation. Microtubules had a length L, and a bending stiffness κ0. Their stiffness was locally reduced to κp/κ0 over a normalized length Δs/L positioned at the arc length s00/L. In this example as well as in all simulations s0/L = 0.33.

b, Examples of microtubule equilibrium shapes in response to distinct combinations local softenings parameters (κp/κ0 and Δs/L) leading to the same apparent bending stiffness (<κ>/κ0=0.5). Shown are also the fits against a model with the constant stiffness 0.5 (full lines).

c, Measurement of the distance ω/L between the shapes of experimental microtubules to shapes of microtubules with a constant rigidity as explained in Methods section. Two examples illustrate a high and low distance suggestive of local and global softening process respectively.

d, Comparison of distances to homogeneous microtubules between experimental observations and simulated microtubules. Colored lines show the theoretical dependence of the distance ω/L on the microtubule deflection Δx/L for different extent of the softened region Δs/L (different colors) and the same given apparent stiffness ⟨κ⟩/κ0 = 0.5. Stars correspond to experimental measurements of the distance ω/L and the deflection Δx/L for different deflection for different microtubules. Shown are only values obtained from microtubules with an apparent stiffness comprised between 0.4 and 0.6 after five bending cycles.