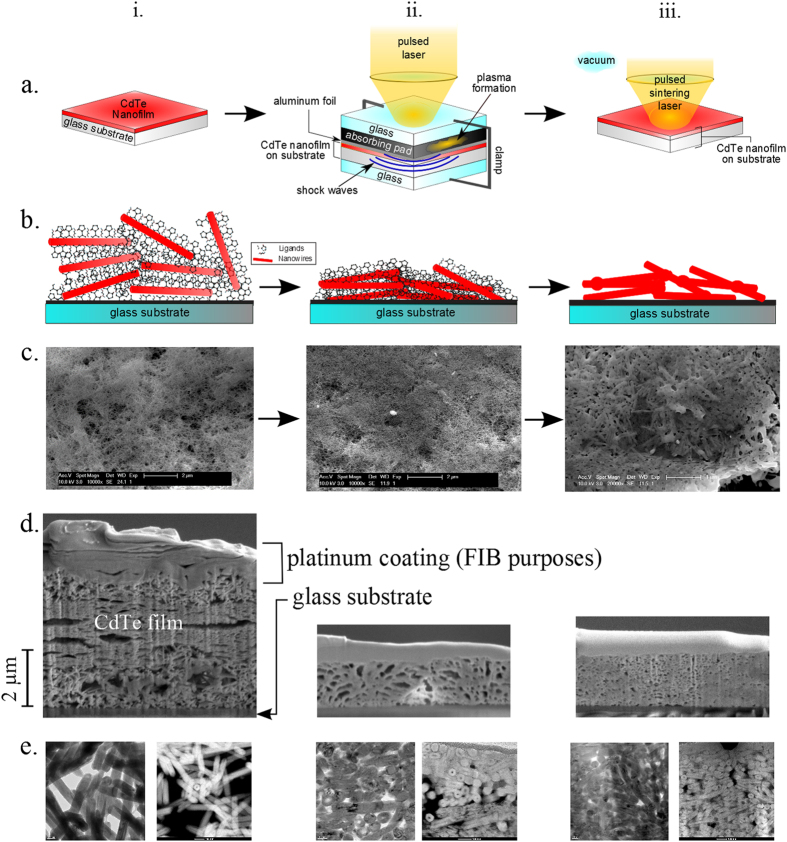

Figure 2. Detailed schematic of the entire laser peen sintering process.

(a) (i) NW film is untreated. (ii) Film undergoes the first stage of processing, the laser peen/shock process. The CdTe substrate is placed between another glass surface and a black-body absorbing material (graphite). A piece of glass is then put on top of the graphite pad to contain it. Next, the laser is shot at the transparent top glass layer in ~5 ns pulses. Plasma is generated from the graphite pad. In turn, shock waves hit the CdTe film in pulses. (iii) Film then undergoes sintering in a separate laser facility. (b) (i) Solution-deposited nanowire films, where nanowires are wrapped with ligands and unconnected; (ii) compressing the film brings the nanowires in better contact; (iii) sintering can remove ligands and strongly join nanowires by forming chemical bonds between them, while general morphology of nanowires are preserved. (c) Top-view SEM images of a CdTe NW film (i) before any treatment16; (ii) after 400 MPa has been applied, and no sintering afterwards16; (iii) after 400 MPa peening and then sintering with two 25-ns pulses. The density of the film greatly increases and the porosity decreases. Note: we have obtained permission from SPIE to reprint images from Figs. 3ci and 3cii. We originally used these in our previous work, reference 16. (d) cross-sectional pieces extracted from a film using the focused ion beam (FIB) technique. (i) untreated; (ii) compressed at 400 MPa; (iii) compressed at 400 MPa and then sintered at 24 mJ/cm2 with two 25 ns pulses. The film thickness and porosity dramatically decrease with treatments. The top coating is platinum, which is layered on the film to assist in the FIB process. These images were cropped from original FIB images for space and clarity purposes. Furthermore, the FIB procedures used to obtain the cross-sectional images were performed on samples after their electrical conductivities were measured. In this way, the platinum and other factors involved in the FIB process did not affect the electrical conductivity measurements. (e) TEM images showing the NW connections after various treatments. (i) untreated; (ii) compressed at 400 MPa, and no sintering afterwards; (iii) compressed at 400 MPa and later sintered.