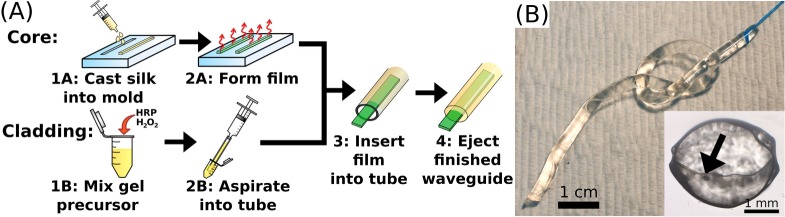

Fig. 1.

Panel A: schematic representation of the construction of silk optical waveguides. To fabricate the core, silk solution is cast into molds (1A) and allowed to dry into films (1B). For the cladding, HRP and H2O2 are added to a silk solution (1B) and aspirated into a PTFE tube (2B). Prior to gelation, the film is inserted into the liquid gel precursor (3). After the gel precursor solidifies, pressure on the syringe ejects the completed waveguide (4). Panel B: photograph of a 9 cm long silk waveguide coupled to a glass optical fiber knotted to show flexibility. Scale bar indicates 1 cm. Inset: Brightfield microscope image of a cross-section of a 3 mm diameter silk waveguide. Scale bar indicates 1 mm. Arrow indicates the silk film core which is 2.9 mm wide and ∼40 μm thick.