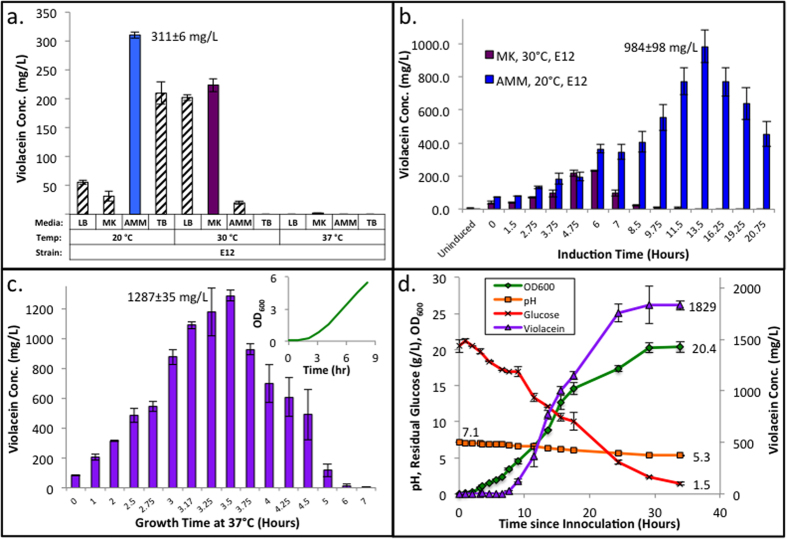

Figure 4. Optimization of fermentation conditions for peak violacein production from strain E12.

(A) Media and temperature optimization show dependent effects for both parameters on violacein production. The two top conditions (AMM, 20 °C) and (MK, 30 °C) were used for further optimization. Error bars represent ± 1 standard deviation of biological triplicate. (B) Induction point optimization of the best conditions as determined in subset A. Time on the x-axis indicates the time between inoculation and induction. Data indicates that fermentation in AMM at 20 °C results in significantly improved peak production over MK media at 30 °C. Error bars represent ±1 standard deviation of biological triplicate. (C) Induction point optimization under improved conditions. Time on the x-axis represents the time the culture was grown at 37 °C. The cultures were then transferred to 20 °C for 1 h prior induction with 1 mM IPTG. Significant improvement in violacein titers were shown by cell growth at 37 °C followed by protein induction and fermentation at 20 °C. Error bars represent ±1 standard deviation of biological duplicate. (D) Demonstration of scale-up potential. Peak production conditions from subset C were used to show violacein production in a 500 mL culture contained in a 2-L baffled shake flask. Significant improvements in titer were obtained presumably due to the differences in growth dynamics and dissolved oxygen levels in baffled shake flask. The larger fermentation volume also allowed for transient analysis of fermentation pH, glucose consumption, absorbance at 600 nm, and violacein production rate. Error bars represent ±1 standard deviation of biological duplicate.