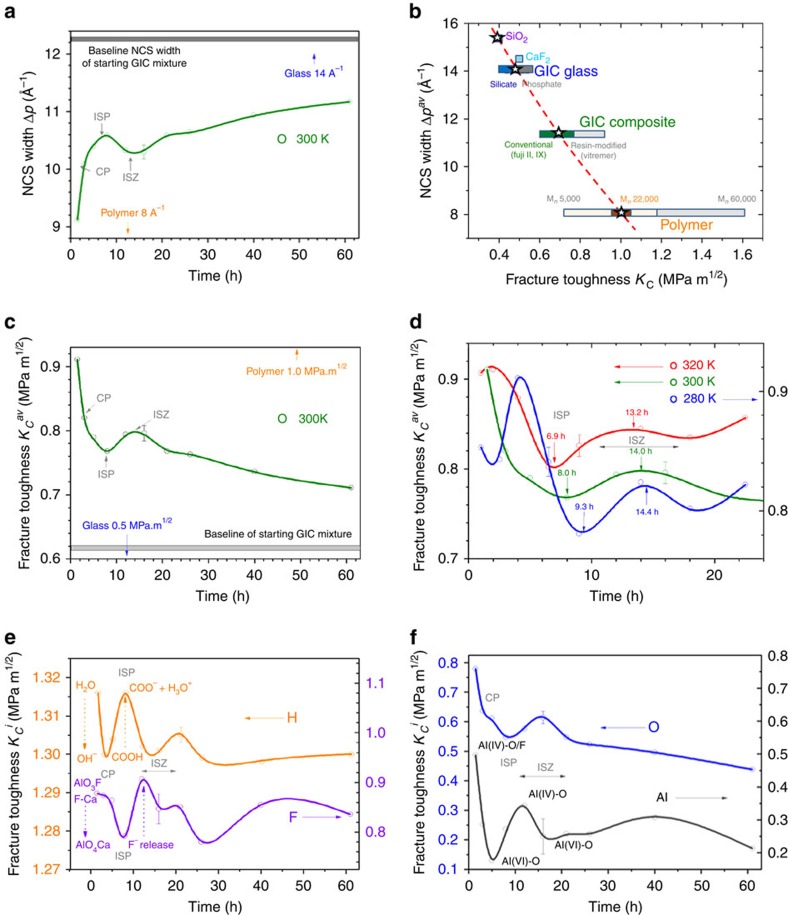

Figure 3. Non-monotonic advancement in atom cohesion and fracture toughness during GIC solidification.

(a) Overall GIC NCS peak width Δpav variations with setting time, measuring different stages in atomic cohesion during setting: CP, ISP and ISZ (see text for details). (b) Inverse relationship between atomic cohesion Δpav and fracture toughness KCav of GIC, polymer and glass (asterisks) and associated materials (see text for details). (c) Non-monotonic fall in overall KCav with setting time at 300 K obtained from overall Δpav a using b, identifying CP and reaction points ISP and ISZ. (d) KCav(280 K), KCav(300 K) and KCav(320 K), showing shifts in ISP and ISZ with setting temperature. (e) Fluctuations in KCi for H and F, showing evidence for hydration and fluorination. (f) KCi for O and Al through the various setting stages. Elemental fracture toughness KCi were derived from Δpi values (Supplementary Fig. 3a), with KCav (280, 300 and 320 K) obtained from Δpav (280, 300 and 320 K) values (Supplementary Fig. 3b), in each case using b.