Table 2.

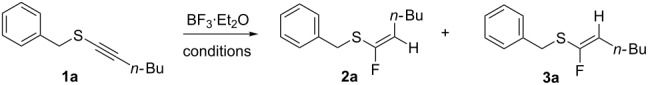

Optimisation of BF3·Et2O/3HF·Et3N mediated hydrofluorination.

| |||||||

| Entry | BF3·Et2O (equiv) |

3HF·Et3N (equiv) |

Time | Temp. | Solvent | Conversion | Yield |

| 1 | 1.5 | 3.0 | 16 h | 0 °C to rt | DCM | >90% | 35% |

| 2 | 1.5 | 3.0 | 5 h | 0 °C to rt | DCM | 39% | 28% |

| 3 | 1.0 | 2.0 | 16 h | 0 °C to rt | DCM | >80% | 30% |

| 4 | 0.5 | 3.0 | 16 h | 0 °C to rt | DCM | – | – |

| 5 | 1.5 | 3.0 | 5 days | 0 °C | DCM | 20% | – |

| 6 | 1.5 × 2 | 3.0 | 7 h | 0 °C | DCM | 20% | – |

| 7 | 1.5 | 3.0 | 5 h | 40 °C | DCM | >95% | 30% |

| 8a | 1.5 | 3.0 | 16 h | 0 °C to rt | DCM | 70% | 28% |

| 9 | 1.5 × 2 | 3.0 × 2 | 21 h | b | THF | 25% | – |

| 10 | 1.5 | 3.0 | 16 h | 0 °C to rt | DCE | <5% | – |

| 11 | 1.5 | 3.0 | 21 h | c | DCE | 10% | – |

| 12 | 1.5 x 2 | 3.0 x 2 | 21 h | d | DCE | n.a.e | – |

aBF3·Et2O and 3HF·Et3N were pre-mixed at 0 °C prior to adding starting material 1a. bMixture stirred for 16 hours at room temperature, then heated to 50 °C for 5 hours. cMixture stirred for 16 hours at room temperature, then stirred under reflux for 5 hours. dMixture stirred for 5 hours at room temperature, then stirred under reflux for 16 hours. eSubstrate decomposed.