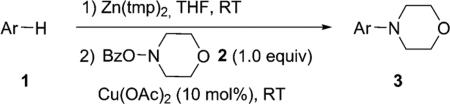

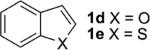

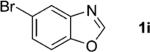

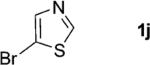

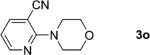

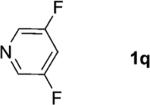

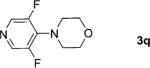

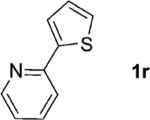

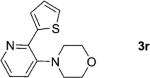

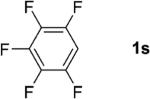

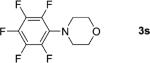

Table 2.

Amination of heteroarenes and arenes.[a]

| ||||

|---|---|---|---|---|

| Entry | 1 | t [h][b] | 3 | Yield [%][c] |

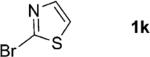

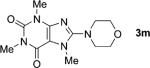

| 1 |

|

1; 5 |

|

96 |

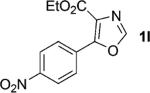

| 2 | 1; 5 | 93 | ||

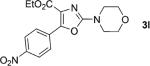

| 3 | 1; 5 | 95 | ||

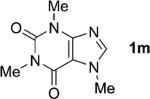

| 4 |

|

1;[d] 5 |

|

71 |

| 5 | 1;[d] 5 | 70 | ||

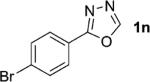

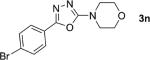

| 6 |

|

1; 12 |

|

82 |

| 7 | 1; 12 | 92 | ||

| 8 | 1; 12 | 95 | ||

| 9 |

|

1; 24 |

|

96 |

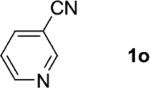

| 10 |

|

1; 5 |

|

85 |

| 11 |

|

1; 5 |

|

90 |

| 12 |

|

1; 4 |

|

89 |

| 13 |

|

1;[e] 24 |

|

82 |

| 14 |

|

1; 4 |

|

91 |

| 15 |

|

2; 12[f] |

|

81 |

| 16 |

|

2; 12[f] |

|

79 |

| 17 |

|

2; 12[f] |

|

91 |

| 18 |

|

2; 12[f] |

|

74 |

| 19 |

|

1; 12 |

|

75 |

Reactions typically run on 0.2 mmol scale. 1 (2.1 equiv), 2 (1.0 equiv, 0.08 m), Zn(tmp)2 (1.0 equiv).

Reaction time for deprotonation and amination step respectively.

Yield of isolated product.

Zn-(tmp)2·LiCl·MgCl2[4g] was used as base to form stable zincate intermediates.

Deprotonation step run in CH2Cl2 because of the poor solubility of 1m in THF.

Amination step run at 50°C.