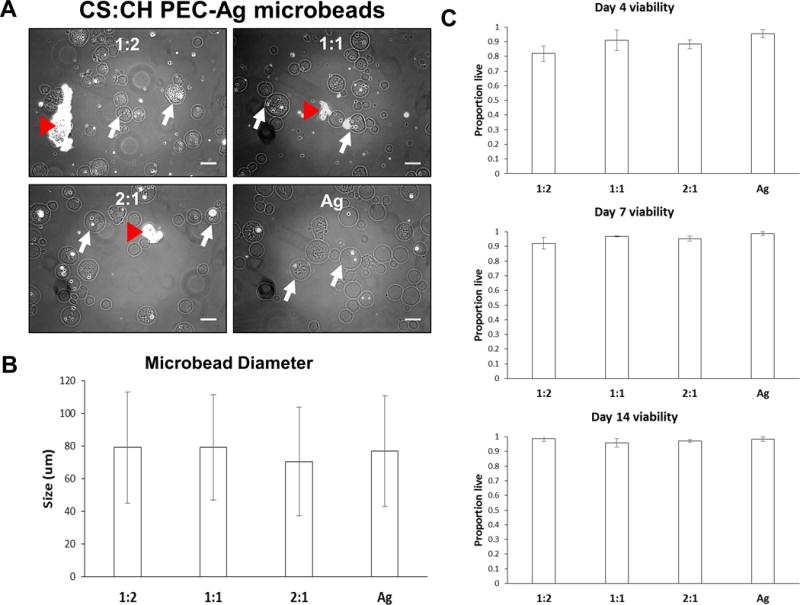

Figure 4.

Spherical PEC-Ag microbeads made with 1:2, 1:1 and 2:1 CS:CH mass ratios. Pure agarose microbeads were also produced for comparison. A) Brightfield images of microbeads taken at day 10. Representative microbeads indicated with white arrow. Substantial incorporation of cells and small PEC particles was observed, though some larger PEC particles were not encapsulated. As with PEC-only particles, cells encapsulated in PEC-Ag microbeads retained a rounded morphology due to a lack of cell adhesion sites in the constituent materials. B) Mean microbead diameters were 70–80μm and did not vary significantly across formulations. Microbead diameter and size distributions are inversely proportional to the mixing speed used during emulsification. A low mixing speed (700rpm) was used to produce a mean bead diameter large enough for cell and PEC encapsulation. C) Quantification of viability of MSC embedded in microbeads. Cell viability within PEC-Ag microbeads was improved compared to PEC particles alone (see Fig.2). Scale bar = 100 μm.