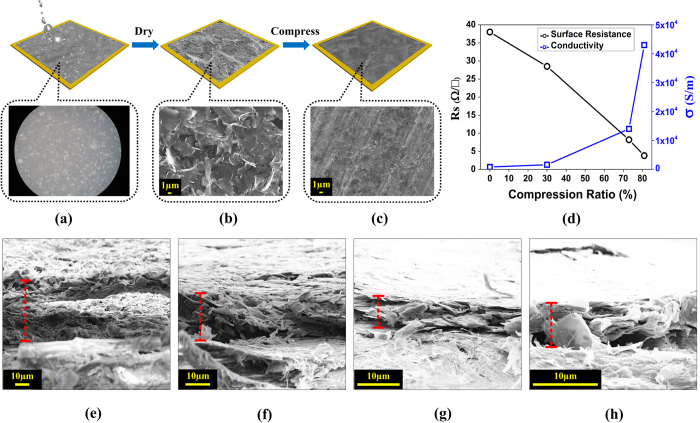

Figure 1. Schematic illustration of preparing printed graphene and its characteristics.

(a) Graphene nanoflake ink is coated on substrate, (b) After drying, highly porous graphene nanoflakes coating forms, (c) Highly dense printed graphene is obtained with compression, (d) Conductivity and surface resistance under different compression ratios. (e) Cross sectional SEM image of uncompressed sample, with thickness around  . (f) Cross sectional SEM image of sample with compression ratio 30%, with average thickness around

. (f) Cross sectional SEM image of sample with compression ratio 30%, with average thickness around  . (g) Cross sectional SEM image of sample with compression ratio 73%, with thickness around

. (g) Cross sectional SEM image of sample with compression ratio 73%, with thickness around  . (h) Cross sectional SEM image of sample with compression ratio 81%, with thickness around

. (h) Cross sectional SEM image of sample with compression ratio 81%, with thickness around  .

.