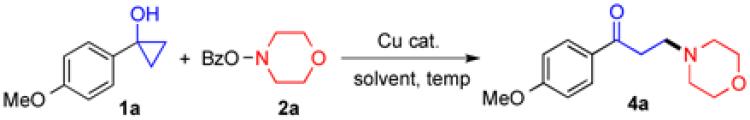

Table 1.

Reaction condition optimization.a

| ||||

|---|---|---|---|---|

|

| ||||

| entry | Cu cat. | solvent | temp (°C) | yield (%)a |

|

| ||||

| 1 | CuI | THF | 80 | 85b |

| 2 | CuI | THF | 80 | 88 |

| 3 | CuI | toluene | 80 | 75 |

| 4 | CuI | DCE | 80 | 65 |

| 5 | CuI | 1,4-dioxane | 80 | 82 |

| 6 | CuI | MeCN | 80 | 90 |

| 7 | - | MeCN | 80 | 0 |

| 8 | CuI | MeCN | rt | 39 |

| 9 | CuI | MeCN | 50 | 93 |

| 10 | CuCl | MeCN | 50 | 88 |

| 11 | CuBr | MeCN | 50 | 98 |

| 12 | CuBr | MeCN | 50 | 93b |

| 13 | CuBr | MeCN | 50 | 80c |

| 14 | CuBr | MeCN | 50 | traced |

General reaction conditions: A solution of 1a (0.15 mmol), 2a (0.1 mmol), and Cu(I) catalyst (0.1 equiv) were stirred until no more starting material left. The reaction process was monitored by thin-layer chromatography. Isolated yield from flash chromatography was given;

1/1 of 1a/2a (0.1 mmol);

1a (0.1 mmol) and 2a (0.15 mmol);

Phenanthroline (0.1 equiv).