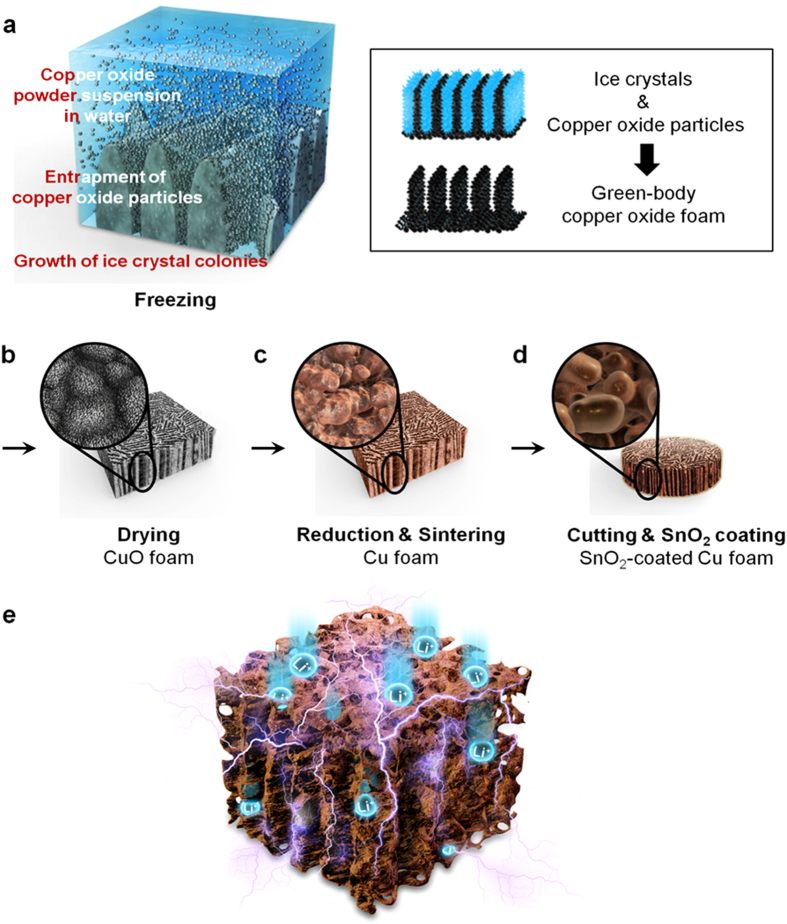

Figure 1. Electrode fabrication and architecture.

(a–d) Schematic diagram of a fabrication process for SnO2-coated Cu foam electrode. (a) During directional freezing of CuO slurry, growth of vertical ice crystal colonies occurred simultaneously with entrapment of CuO particles between the ice crystals structure. A porous body structure was formed as a replica of the ice crystals (right box). (b) After drying of the ice, a porous layer-by-layer structure resulted, consisting of lightly-bound CuO particles. (c) The CuO foam was then sintered and reduced from dark green CuO to orange Cu in a hydrogen atmosphere. (d) A SnO2 sol-gel coating method was employed to fabricate a SnO2-coated Cu foam electrode. (e) Conceptual diagram of the SnO2-coated Cu foam with continuous metallic and porous structure enabling both effective electron and Li ion pathways and also stress alleviation in volume changes of SnO2 coating layer during cycling.