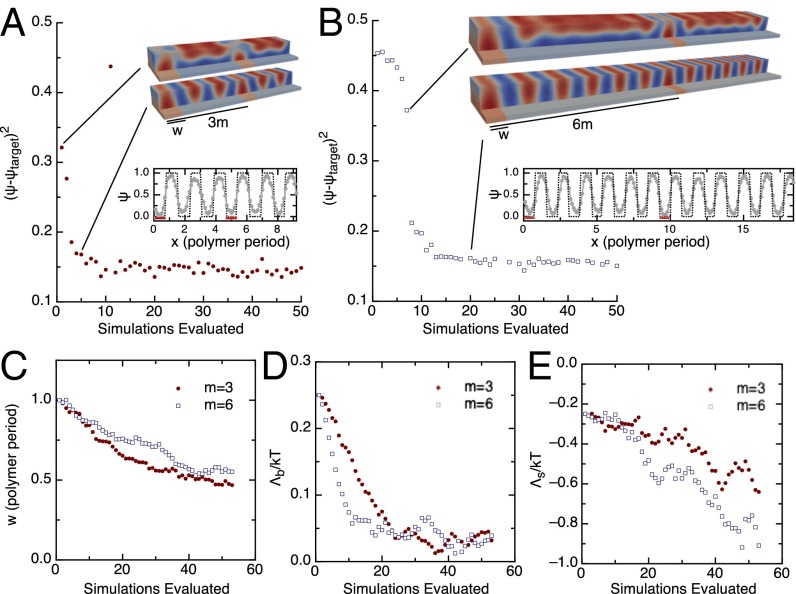

Fig. 5.

Optimizing directed self-assembly. Here we design the width of the stripe, the strength of its attraction to the red polymer beads , and the attraction strength of the background substrate toward the blue polymer beads, to match the self-assembled phase as closely as possible to the target of alternating stripes. We quantify the success of our optimizer by comparing an order parameter binned along the x axis of the box and averaged over y and z to the target stripe pattern. With Eq. 2, we are able to produce optimized parameters for 3× (A) and 6× (B) density multiplication after simulating 10 and 20 parameter choices. Two characteristic configurations are plotted in A and B, Insets, separated by just a handful of iterations, yet displaying markedly different phases of the polymer. Asymptotic configurations depicting Ψ (solid, marked line) and the target (dashed line) (A and B, Insets) show that the optimized parameters match the desired morphology, typically within or better. In plotting the parameters generated by Eq. 2 (C–E), we find that the interaction with the background brush is the most relevant parameter in directed self-assembly. For both the 6× and 3× problems, the rapid convergence toward the optimized state takes place once the background strength is reduced to . After a weak background is established, the strip width and strength function as fine-tuning parameters that facilitate defect-free assembly.